33

SeguidoresFabricanteLeistritz Produktionstechnik GmbH

Grupo de producto Roscadora | Roscadoras

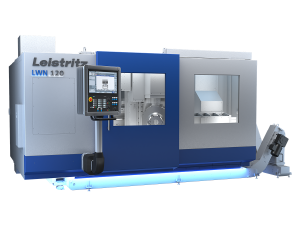

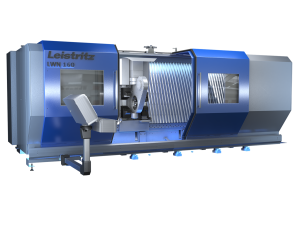

Nombre del productoLWN 120 IW - Innenwirbeln

Description

Innovation at the EMO: complete machining of nuts Designed for the production of complex recirculating ball nuts and other internal threads, Leistritz is presenting a new machine at the EMO which performs complete machining and surpasses standard methods such as hard turning or grinding when it comes to precision and productivity. The combination of a CNC-controlled internal whirling process with an integrated hard turning method ensures considerably greater productivity during the complete machining of nuts with functional surfaces, as Leistritz will demonstrate at the EMO with the aid of challenging components which were produced on the new LWN 120 IW. This is made possible thanks to a precision-ground carbide plate which already contains the complete profile. As a result, a reproducible profile quality can be achieved, which would otherwise only be possible with a complex grinding process. The key advantage is that as the profile plate is only moved into the workpiece once per thread turn during internal whirling, productivity is also raised by a factor of 3 compared to turning or grinding. To be specific, the whirling tool with the profile plate moves across the entire workpiece with a maximum length of 800 mm and a diameter of 12 to 200 mm. The high-precision profiling takes place from the workpiece to the oscillator. To generate the cutting speed, the workpiece rotates around the tool at up to 150 rpm. The spindle of the tool itself rotates at 5 to 2,400 rpm and in doing so, oscillates linearly in parallel, so that the profiled cutting plate is always perpendicular to the thread profile. The cutting depth is set via the CNC control system through the machine’s X-axis. In this way, the entire internal profile can be created in a single pass from back to front. With a Z-axis travel path of 1,100 mm in the horizontal direction and an X-axis stroke of 182 mm, the majority of internal profiles can be created on the new internal whirling machine: in addition to all conceivable thread geometries, ball screw nuts with a lead of 40 mm and a diameter of 40 mm, or a lead of 80 mm with a 40 mm diameter, can be fully machined with the highest geometrical quality in a single production step. In order to completely machine the functional surfaces, the LWN 120 IW also facilitates turning including the machining of plane surfaces, i.e., the face ends of the nuts. The unique geometry of the ground profile plate actually enables a 100% check to be performed, even if only random checks are made. The new machine for hard whirling of internal profiles also offers a further decisive advantage: it is highly flexible thanks to short set-up and tool changeover times. This also makes the LWN 120 IW a highly interesting option for small batch sizes. Thanks to the dry cutting, there are no costs for cooling lubricants and the short chips can be disposed of inexpensively. To meet customer-specific requirements, Leistritz also offers a modern modular system.

Imágenes de productos