33

SeguidoresFabricanteLeistritz Produktionstechnik GmbH

Grupo de producto Roscadora | Roscadoras

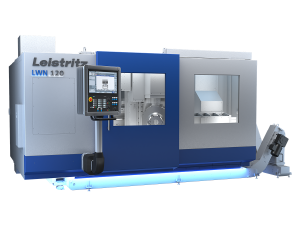

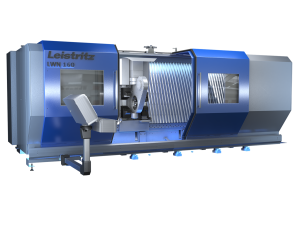

Nombre del productoLWN 100

Description

LWN 100: Perfect for manufacturing EPS screws At this year‘s EMO, Leistritz Produktionstechnik GmbH will present a machine novelty from its successful LWN series, amongst others. Hannover (June 21, 2017) – At the industry’s key event – the EMO 2017 in Hannover – German?based Leistritz Produktionstechnik GmbH will introduce the LWN 100, a new machine specifically for whirling EPS screws. “With this machine we meet the high requirements of the automotive industry,“ says Klaus Theusner, Managing Director at Leistritz Produktionstechnik GmbH. “The degree of efficiency and quietness play a very important role in steering technology. They can only be achieved through highest profile accuracy and finish quality of EPS screws.“ LWN 100 advantages The greatest asset of the new and compact LWN 100 is its ability to whirl ready?to?install EPS screws. It achieves very high finish quality which optimally satisfies the latest steering generation’s demands in terms of torque and noise characteristics. The whirling is a dry machining process. Not only does it bring enormous cost savings for the purchase and disposal of coolants and cutting fluids. Additionally, it is eco?friendly and keeps the working environment clean. The combination of a new digital control unit, a dynamic drive and a compact machine design results in shorter cycle times. Thus, work pieces can be manufactured even more costeffectively. The new, high?precision Leistritz whirling machine is therefore particularly adjusted to the high demands of series production, which in addition to a very good quality require flexibility and economic processing times. “The LWN 100 even stands out when it comes to Industry 4.0 features“, says Theusner. “By using so?called Smart Software Tools, the machine can easily be operated and integrated.“

Imágenes de productos