Precision by tradition

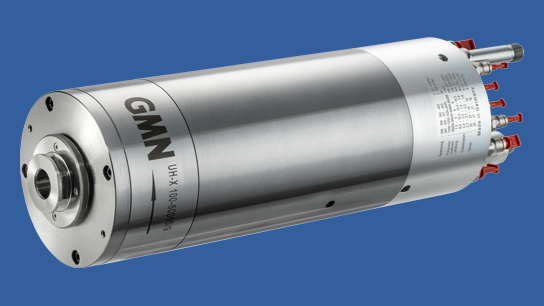

New UH spindle series with integrated IIoT technology "IDEA-4S"

At GrindingHub 2024, from May 14 to 17 in Stuttgart, GMN will be presenting the new UH spindle series for external and internal grinding with the embedded system "IDEA-4S" to the grinding industry in Hall 9 at Stand B81.

The models of the new UH series have a significantly higher level of efficiency, are vibration-optimized and offer greater dynamic rigidity. They are also cost-effective to maintain and resource-saving to operate.

They are also the first spindles with integrated IIoT technology IDEA-4S for comprehensive Industry 4.0 connectivity. The embedded system and intelligent sensor technology make the spindles powerful, highly effective and communicative.

Integrated into an overall digital concept, they promise new solutions for efficient machining.

Four sizes each for milling and grinding applications

The spindles are available as UH-X models for internal grinding and with the designation UH-P for milling applications with HSK interfaces for manual tool changes. Four sizes are available with housing diameters of 100, 120, 150 and 170 mm. Depending on the model, the outputs range up to 32 kW and the speeds up to a maximum of 120,000 rpm.

Efficient: Better results with a third less installed power

With the new spindle series, GMN is using synchronous drives for the first time, which make it possible to reduce losses, particularly in the partial load range that dominates grinding. This means that the power range of the spindles is better utilized and a higher degree of efficiency is achieved.

In addition, the rotor operates resource-efficiently at a lower temperature - instead of 200 ºC, it heats up to less than 100 ºC.

Users can therefore use UH models with a third less installed power for comparable applications compared to previously used spindles. The inverter and control cabinet can also be made smaller, and a choke can be dispensed with entirely.

Better machining quality

Despite the lower installed power, the UH spindles achieve the same or better machining results. This is because the synchronous motors with their higher power density enable larger bearings and shaft diameters and correspondingly larger tool interfaces. The higher power density allows for more compact assemblies and shorter shafts with smoother running. In addition, the improved dynamic rigidity and load capacity of the spindle allows higher critical speeds.

Direct connection to IIoT infrastructures

For the first time, the embedded system IDEA-4S, Integrated Data Acquisition and Evaluation for Spindles, developed by GMN, is being used as standard on this spindle series. It permanently records and processes process values such as bearing and coolant temperature, speed, vibrations and optional misalignments.

This information is evaluated by IDEA-4S while still in the spindle. It is then transmitted by means of a bidirectional signal via IO-Link for communication with the machine controller and in production networks. In this way, the user is continuously informed during operation about how he can make the best possible use of his spindle and motor. In addition to the process data, GMN's experience with several hundred thousand spindles in use is also incorporated into the interpretation.

An additional advantage is the digital type plate, which makes installation easier and makes the UH spindles identifiable with their model and test data.

At GrindingHub 2024, from May 14 to 17 in Stuttgart, GMN will be presenting the new UH spindle series for external and internal grinding with the embedded system "IDEA-4S" to the grinding industry in Hall 9 at Stand B81.

The models of the new UH series have a significantly higher level of efficiency, are vibration-optimized and offer greater dynamic rigidity. They are also cost-effective to maintain and resource-saving to operate.

They are also the first spindles with integrated IIoT technology IDEA-4S for comprehensive Industry 4.0 connectivity. The embedded system and intelligent sensor technology make the spindles powerful, highly effective and communicative.

Integrated into an overall digital concept, they promise new solutions for efficient machining.

Four sizes each for milling and grinding applications

The spindles are available as UH-X models for internal grinding and with the designation UH-P for milling applications with HSK interfaces for manual tool changes. Four sizes are available with housing diameters of 100, 120, 150 and 170 mm. Depending on the model, the outputs range up to 32 kW and the speeds up to a maximum of 120,000 rpm.

Efficient: Better results with a third less installed power

With the new spindle series, GMN is using synchronous drives for the first time, which make it possible to reduce losses, particularly in the partial load range that dominates grinding. This means that the power range of the spindles is better utilized and a higher degree of efficiency is achieved.

In addition, the rotor operates resource-efficiently at a lower temperature - instead of 200 ºC, it heats up to less than 100 ºC.

Users can therefore use UH models with a third less installed power for comparable applications compared to previously used spindles. The inverter and control cabinet can also be made smaller, and a choke can be dispensed with entirely.

Better machining quality

Despite the lower installed power, the UH spindles achieve the same or better machining results. This is because the synchronous motors with their higher power density enable larger bearings and shaft diameters and correspondingly larger tool interfaces. The higher power density allows for more compact assemblies and shorter shafts with smoother running. In addition, the improved dynamic rigidity and load capacity of the spindle allows higher critical speeds.

Direct connection to IIoT infrastructures

For the first time, the embedded system IDEA-4S, Integrated Data Acquisition and Evaluation for Spindles, developed by GMN, is being used as standard on this spindle series. It permanently records and processes process values such as bearing and coolant temperature, speed, vibrations and optional misalignments.

This information is evaluated by IDEA-4S while still in the spindle. It is then transmitted by means of a bidirectional signal via IO-Link for communication with the machine controller and in production networks. In this way, the user is continuously informed during operation about how he can make the best possible use of his spindle and motor. In addition to the process data, GMN's experience with several hundred thousand spindles in use is also incorporated into the interpretation.

An additional advantage is the digital type plate, which makes installation easier and makes the UH spindles identifiable with their model and test data.