Precision by tradition

New patented freewheel clutch geometry from GMN: More powerful, lighter, cheaper

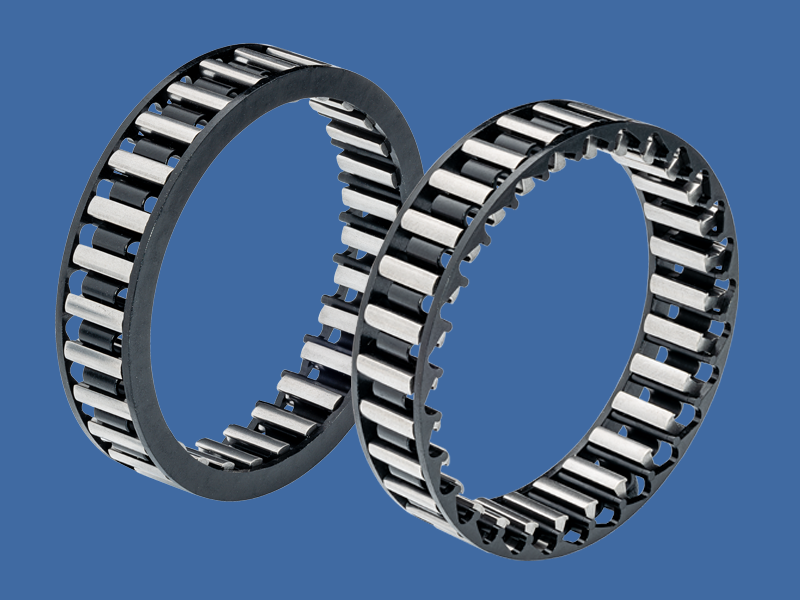

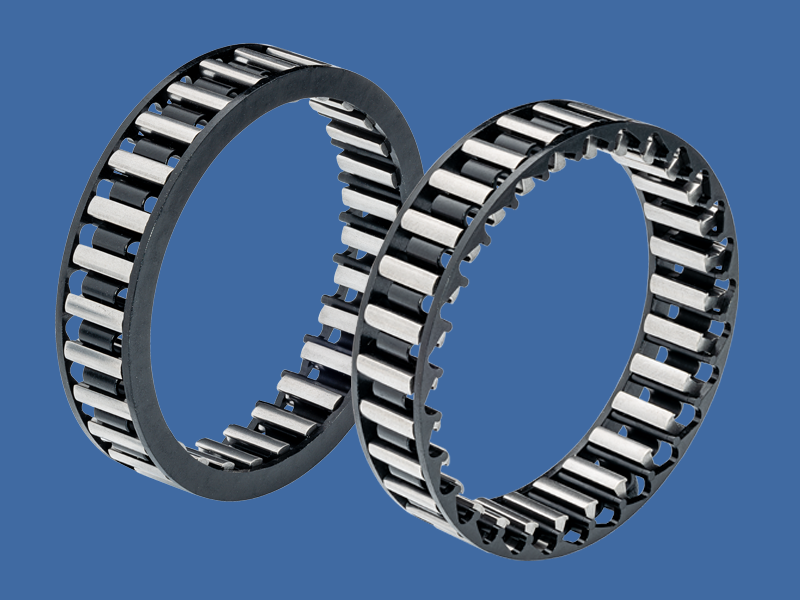

Freewheel clutches are an essential component of electric and conventional bicycles. Conventional models require a spring for power transmission. An innovative freewheel clutch from drive technology specialist GMN does away with this. Its new, patent-pending spring-loaded cage geometry offers a whole range of advantages. It enables one of the most powerful freewheel clutches currently available.

In sprag type freewheel clutches, a spring running in a slot normally straightens the locking elements and makes them available for power transmission. GMN has now completely redesigned this bicycle component: There is no need for a spring; its function is integrated thanks to a spring-loaded cage geometry. Instead, this ensures that the sprags straighten up. The function remains the same: The freewheel clutch then clamps in one direction and transmits the force applied.

Manfred Elbacher, Head of Drive Technology at GMN, enthuses: “As far as I know, our innovation is the only freewheel clutch with patented cage spring suspension without a spring. For me, it is the most convincing product since I joined the company in 1992.”

Freewheel clutch cage takes over the function of the spring

When installing the new freewheel clutch cage, the sprags are clicked into the so-called sprag pockets and a spring-loaded overlap ensures that they can no longer fall out of the cage.

An elastic force is then applied to the sprags in the installation position of the freewheel clutch by a special design of the cage pockets, which straightens the sprags. This ensures frictional contact with the connecting parts.

Most higher-end e-bikes are equipped with two freewheel clutches that couple and decouple the two drive systems: one for the transmission of muscle power via the pedals and the other for the supporting electric motor. This innovative product can be used for both purposes. Various standard catalog versions as well as customer-specific versions are planned.

Another distinguishing feature of GMN freewheel clutches compared to models from other suppliers is that they are generally friction-locked and therefore friction-locked - in contrast to the widely used latch locks, which work via a positive fit. This is why they do not “click”.

Freewheel clutches for more than forty years

The Nuremberg-based specialist for drive technology has built up extensive expertise in freewheel clutches over a long period of time. GMN has been offering this important component since the late 1960s, and since the 1990s also specifically for bicycles. Since 2014, the company has been increasingly represented with them for e-bikes, and production has multiplied during this time.

Numerous advantages in bicycle and e-bike production

In addition to GMN as a component manufacturer, customers, bicycle manufacturers and ultimately cyclists will all benefit from this innovation. A whole range of advantages already come into play during production. Until now, special slots had to be milled into the sprags for the springs during production. Deviations in the width or depth of the slot during milling could lead to rejects, as could a spring not running properly in the slot.

The entire processing step can now be dispensed with, as can the purchase and storage of springs.

Eliminating the spring also saves weight. This is because the elimination of the slot extends the line contact between the sprags and the connecting parts. The transmittable torque per sprag increases, which is why significantly fewer sprags are required for power transmission. This leads to a significantly lower weight of the freewheel clutch “This advantage is particularly well received by customers,” reports Elbacher.

Production is faster, safer and cheaper

The new design also makes itself felt in several ways during assembly. In manual production, employees benefit from the fact that they save time during installation and require fewer assembly aids compared to a conventional freewheel clutch. If the process is automated, the cycle time is reduced.

Another advantage is increased process reliability in assembly and in the end product. “We need fewer components for production, which is also simpler and safer. In addition, there are no procurement risks for the springs along the supply chain. This is a factor that should not be underestimated, as we have seen during the pandemic,” explains Elbacher.

Solid and reliable

As the innovative cage geometry simplifies the design of the new freewheel clutch, the number of possible causes of failure is reduced. This makes the component more solid, more efficient and more reliable in everyday use.

“Our innovation therefore offers bicycle and e-bike riders a lighter and more reliable component,” concludes Manfred Elbacher.

Freewheel clutches are an essential component of electric and conventional bicycles. Conventional models require a spring for power transmission. An innovative freewheel clutch from drive technology specialist GMN does away with this. Its new, patent-pending spring-loaded cage geometry offers a whole range of advantages. It enables one of the most powerful freewheel clutches currently available.

In sprag type freewheel clutches, a spring running in a slot normally straightens the locking elements and makes them available for power transmission. GMN has now completely redesigned this bicycle component: There is no need for a spring; its function is integrated thanks to a spring-loaded cage geometry. Instead, this ensures that the sprags straighten up. The function remains the same: The freewheel clutch then clamps in one direction and transmits the force applied.

Manfred Elbacher, Head of Drive Technology at GMN, enthuses: “As far as I know, our innovation is the only freewheel clutch with patented cage spring suspension without a spring. For me, it is the most convincing product since I joined the company in 1992.”

Freewheel clutch cage takes over the function of the spring

When installing the new freewheel clutch cage, the sprags are clicked into the so-called sprag pockets and a spring-loaded overlap ensures that they can no longer fall out of the cage.

An elastic force is then applied to the sprags in the installation position of the freewheel clutch by a special design of the cage pockets, which straightens the sprags. This ensures frictional contact with the connecting parts.

Most higher-end e-bikes are equipped with two freewheel clutches that couple and decouple the two drive systems: one for the transmission of muscle power via the pedals and the other for the supporting electric motor. This innovative product can be used for both purposes. Various standard catalog versions as well as customer-specific versions are planned.

Another distinguishing feature of GMN freewheel clutches compared to models from other suppliers is that they are generally friction-locked and therefore friction-locked - in contrast to the widely used latch locks, which work via a positive fit. This is why they do not “click”.

Freewheel clutches for more than forty years

The Nuremberg-based specialist for drive technology has built up extensive expertise in freewheel clutches over a long period of time. GMN has been offering this important component since the late 1960s, and since the 1990s also specifically for bicycles. Since 2014, the company has been increasingly represented with them for e-bikes, and production has multiplied during this time.

Numerous advantages in bicycle and e-bike production

In addition to GMN as a component manufacturer, customers, bicycle manufacturers and ultimately cyclists will all benefit from this innovation. A whole range of advantages already come into play during production. Until now, special slots had to be milled into the sprags for the springs during production. Deviations in the width or depth of the slot during milling could lead to rejects, as could a spring not running properly in the slot.

The entire processing step can now be dispensed with, as can the purchase and storage of springs.

Eliminating the spring also saves weight. This is because the elimination of the slot extends the line contact between the sprags and the connecting parts. The transmittable torque per sprag increases, which is why significantly fewer sprags are required for power transmission. This leads to a significantly lower weight of the freewheel clutch “This advantage is particularly well received by customers,” reports Elbacher.

Production is faster, safer and cheaper

The new design also makes itself felt in several ways during assembly. In manual production, employees benefit from the fact that they save time during installation and require fewer assembly aids compared to a conventional freewheel clutch. If the process is automated, the cycle time is reduced.

Another advantage is increased process reliability in assembly and in the end product. “We need fewer components for production, which is also simpler and safer. In addition, there are no procurement risks for the springs along the supply chain. This is a factor that should not be underestimated, as we have seen during the pandemic,” explains Elbacher.

Solid and reliable

As the innovative cage geometry simplifies the design of the new freewheel clutch, the number of possible causes of failure is reduced. This makes the component more solid, more efficient and more reliable in everyday use.

“Our innovation therefore offers bicycle and e-bike riders a lighter and more reliable component,” concludes Manfred Elbacher.