Precision by tradition

High-precision ball bearings from GMN now in P4+ and UP+ accuracy classes

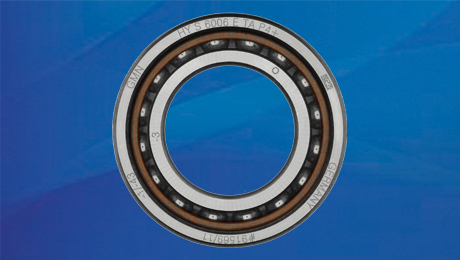

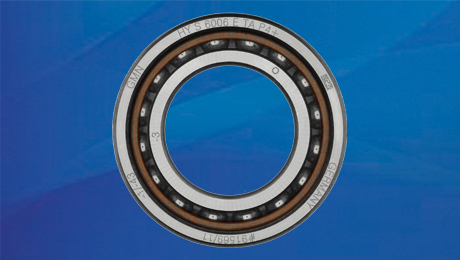

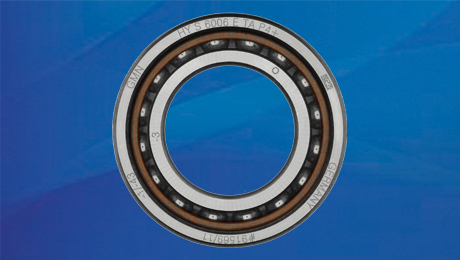

GMN spindle ball bearings are now also available in the P4+ and UP+ high precision accuracy classes. The new P4+ class is successively replacing the previous DIN P4 and ABEC 7 accuracy classes. The new premium “Ultra Precision” UP+ accuracy class meets even higher requirements for running, shape and dimensional accuracy. With the new accuracy classes, GMN is increasing the reliability and performance of its spindle ball bearings to meet the highest requirements for precision and quality.

In addition, the marking has also been improved. For instance, all the important data, including the bore deviations, the outside diameter, width and production lot can be seen on the outside of the rings in addition to the packaging. In addition, a QR code on the packaging allows all the data to be read out via smartphones or readers and integrated into a variety of database solutions. No additional software or internet connection is needed. This way, customers can identify the product more quickly and easily and better anti-counterfeiting security is provided.

Ball bearings for high-speed spindles

With the high-precision ball bearings of the new P4+ and UP+ accuracy classes, GMN offers the components needed to meet the increased demands of the machine tool industry in terms of speed, running accuracy, service life and machining precision.

The P4+ tolerance class fulfils the running and forming accuracy demands in accordance with DIN P2 / ISO 2 and dimensional accuracy in accordance with DIN P4 / ISO 4. It is intended as a standard accuracy class for a wide range of applications in the machine tool industry and is available in all designs and series with bore diameters from 5 to 120 mm.

Ball bearings of the UP+ tolerance class have been conceived for applications where very high demands are placed on such performance parameters as speed, running accuracy and vibration. UP+ spindle ball bearings meet the running and forming accuracies as demanded by DIN P2 / ISO 2 or better and they are available in the S and SM types, as well as 60 and 62 series with bore diameters between 5 and 70 mm.

A large selection of standard solutions and custom-made products

High-precision spindle ball bearings from GMN are optimized for high speeds, loads and rigidity and are characterized by a long service life and reliability. They can be configured in many ways, so that the right design exists for almost any requirement. They are available in various designs and series, with a number of types of cages. They are also available in different materials, as well as with balls made of 100Cr6 roller bearing steel or ceramics.

The product range includes high-precision spindle ball bearings with bore diameters ranging from 5 to 120 mm and a variety of nominal contact angles, accuracies and preloads. GMN manufactures all its ball bearings in Nuremberg. Only high-quality materials and substances are used in all the components and manufacturing processes. Special application-optimized, custom designs are also available on request in addition to standard solutions.

GMN spindle ball bearings are now also available in the P4+ and UP+ high precision accuracy classes. The new P4+ class is successively replacing the previous DIN P4 and ABEC 7 accuracy classes. The new premium “Ultra Precision” UP+ accuracy class meets even higher requirements for running, shape and dimensional accuracy. With the new accuracy classes, GMN is increasing the reliability and performance of its spindle ball bearings to meet the highest requirements for precision and quality.

In addition, the marking has also been improved. For instance, all the important data, including the bore deviations, the outside diameter, width and production lot can be seen on the outside of the rings in addition to the packaging. In addition, a QR code on the packaging allows all the data to be read out via smartphones or readers and integrated into a variety of database solutions. No additional software or internet connection is needed. This way, customers can identify the product more quickly and easily and better anti-counterfeiting security is provided.

Ball bearings for high-speed spindles

With the high-precision ball bearings of the new P4+ and UP+ accuracy classes, GMN offers the components needed to meet the increased demands of the machine tool industry in terms of speed, running accuracy, service life and machining precision.

The P4+ tolerance class fulfils the running and forming accuracy demands in accordance with DIN P2 / ISO 2 and dimensional accuracy in accordance with DIN P4 / ISO 4. It is intended as a standard accuracy class for a wide range of applications in the machine tool industry and is available in all designs and series with bore diameters from 5 to 120 mm.

Ball bearings of the UP+ tolerance class have been conceived for applications where very high demands are placed on such performance parameters as speed, running accuracy and vibration. UP+ spindle ball bearings meet the running and forming accuracies as demanded by DIN P2 / ISO 2 or better and they are available in the S and SM types, as well as 60 and 62 series with bore diameters between 5 and 70 mm.

A large selection of standard solutions and custom-made products

High-precision spindle ball bearings from GMN are optimized for high speeds, loads and rigidity and are characterized by a long service life and reliability. They can be configured in many ways, so that the right design exists for almost any requirement. They are available in various designs and series, with a number of types of cages. They are also available in different materials, as well as with balls made of 100Cr6 roller bearing steel or ceramics.

The product range includes high-precision spindle ball bearings with bore diameters ranging from 5 to 120 mm and a variety of nominal contact angles, accuracies and preloads. GMN manufactures all its ball bearings in Nuremberg. Only high-quality materials and substances are used in all the components and manufacturing processes. Special application-optimized, custom designs are also available on request in addition to standard solutions.