TRUMPF lightens the manual workload in 3D printing

TRUMPF is set to present its automated 3D printing solutions at Frankfurt's Formnext fair in a showcase featuring the TruPrint 5000 system. The high-tech company's experts will also demonstrate how powder bed and melt pool monitoring enables quality inspection on the fly during printing. This marks a major stride towards TRUMPF's goal of fully automated, 3D print-driven production, enhancing its skill-set in mass additive manufacturing.

Automation for consistently high quality

A way of integrating 3D printers into automated processing chains has yet to be found. These systems stand apart from the production line and require human operators. However, manual tasks have to be minimized for automated mass manufacturing; otherwise production will take too long and the quality of reproduced parts will vary. TRUMPF has taken the first step by automating the processes within the system. "This is necessary so that upstream and downstream job steps can eventually be connected," says Tobias Baur, head of the 3D printing department at TRUMPF. These new solutions are geared primarily towards the first stage of the process, which involves a great deal of manual effort.

Automated lid removal

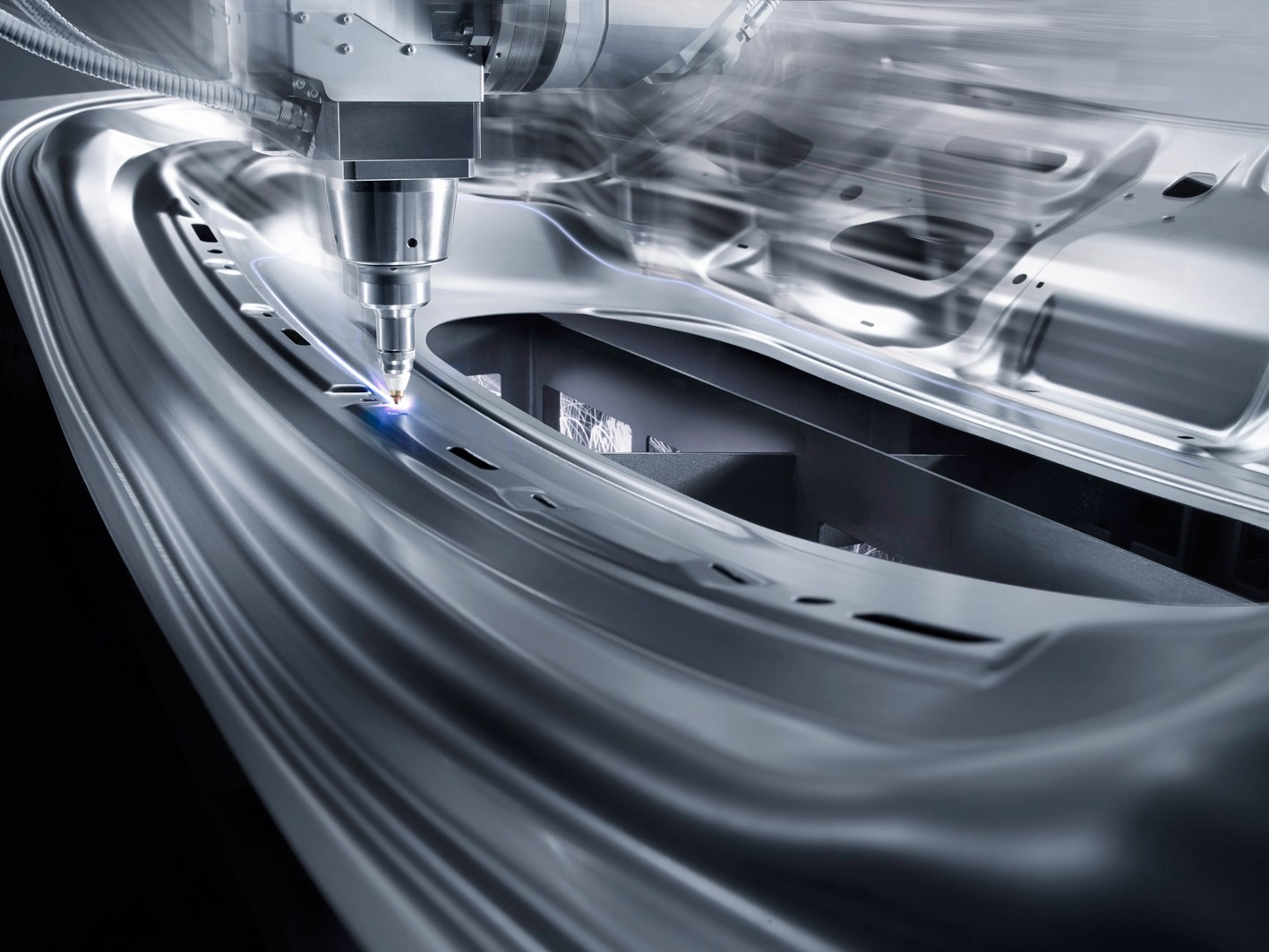

The TruPrint 5000, like all TruPrint models, features Laser Metal Fusion (LMF) technology. This system works according to the multi-laser principle, with three lasers joining forces to melt the component's geometry in the powder bed. Since it can preheat up to 500 degrees Celsius, this system is the first to process heat-resistant materials such as carbon steels. This also improves the machining quality of materials such as titanium, as it reduces stress in the component and requires less reworking.

TRUMPF also aims to unveil a new automated method of handling lids for build and supply cylinders at Formnext. The TruPrint 5000 features dual lids to maximize safety. One lid on the processing chamber conserves the inert gas atmosphere from one printing job to the next. A second lid prevents powder loss during transport. In the past, the operator had to remove and replace both lids by hand after printing. "This takes a long time with preheating up to 500 degrees Celsius because the build chamber has to cool down first," Baur informs.

Now the TruPrint 5000 performs that task. A carriage developed by TRUMPF replaces the recoater's applicator, which spreads the powder coating in the build chamber during printing. The carriage has an insert installed that keeps the lids in place when it travels. TRUMPF developers provided a spot for it to park at the edge of the build chamber. The supply cylinders ascend independently and latch their lids into the processing chamber's ceiling. This places them beyond the laser's scanning range, where they can remain until the process runs its course.

System automatically adjusts the laser and substrate plate

Automation also makes for more reliable 3D printing, as demonstrated by the TruPrint 5000's scanner monitoring and leveling system. It ensures that the three laser beams are properly aligned. To this end, the developers provided the recoater with a calibration target that measures the laser beams' positions and sends the coordinates to a software program. The leveling monitor checks the substrate plate's position. It uses a camera and laser sensor system to gauge the height and orientation when setting up a build job. In the event of any deviation, the operator can adjust the substrate plate to the measuring system's specifications.

Monitoring solutions check the quality after every shift

Industrial mass manufacturing requires automated quality assurance solutions. A flaw such as a tiny furrow or a foreign object in the powder bed will corrupt the printed component. To prevent that, TRUMPF developed several processes to assure the quality of components during printing, one of which is powder bed monitoring. A high-resolution camera in the printer takes a picture of the powder bed after each shift and sends this image to an IT system. It assesses images in real time, detects flaws, and automatically notifies the machine operator. "The images can also serve to analyze faults and sustainably improve the process," says Baur. This IT system also categorizes the fault and provides details to help engineers correct the problem.

At the Formnext fair, TRUMPF experts will also demonstrate how melt pool monitoring tech helps assure quality. The melt pool is a very sensitive part of the process. Even minor fluctuations - for example, in the build chamber's temperature or the powder's composition - can lead to flaws. Diodes in the printer capture the light emitted during the process to monitor the melt pool's quality. The IT system then compares these values with data sourced from a reference component, and graphically displays anomalies such as a cooler or overheated melt pool. The machine operator can see the flaw straightaway and halt the process. This assessment takes place after each coat is applied, as does a similar assessment for powder bed monitoring.

TRUMPF is set to present its automated 3D printing solutions at Frankfurt's Formnext fair in a showcase featuring the TruPrint 5000 system. The high-tech company's experts will also demonstrate how powder bed and melt pool monitoring enables quality inspection on the fly during printing. This marks a major stride towards TRUMPF's goal of fully automated, 3D print-driven production, enhancing its skill-set in mass additive manufacturing.

Automation for consistently high quality

A way of integrating 3D printers into automated processing chains has yet to be found. These systems stand apart from the production line and require human operators. However, manual tasks have to be minimized for automated mass manufacturing; otherwise production will take too long and the quality of reproduced parts will vary. TRUMPF has taken the first step by automating the processes within the system. "This is necessary so that upstream and downstream job steps can eventually be connected," says Tobias Baur, head of the 3D printing department at TRUMPF. These new solutions are geared primarily towards the first stage of the process, which involves a great deal of manual effort.

Automated lid removal

The TruPrint 5000, like all TruPrint models, features Laser Metal Fusion (LMF) technology. This system works according to the multi-laser principle, with three lasers joining forces to melt the component's geometry in the powder bed. Since it can preheat up to 500 degrees Celsius, this system is the first to process heat-resistant materials such as carbon steels. This also improves the machining quality of materials such as titanium, as it reduces stress in the component and requires less reworking.

TRUMPF also aims to unveil a new automated method of handling lids for build and supply cylinders at Formnext. The TruPrint 5000 features dual lids to maximize safety. One lid on the processing chamber conserves the inert gas atmosphere from one printing job to the next. A second lid prevents powder loss during transport. In the past, the operator had to remove and replace both lids by hand after printing. "This takes a long time with preheating up to 500 degrees Celsius because the build chamber has to cool down first," Baur informs.

Now the TruPrint 5000 performs that task. A carriage developed by TRUMPF replaces the recoater's applicator, which spreads the powder coating in the build chamber during printing. The carriage has an insert installed that keeps the lids in place when it travels. TRUMPF developers provided a spot for it to park at the edge of the build chamber. The supply cylinders ascend independently and latch their lids into the processing chamber's ceiling. This places them beyond the laser's scanning range, where they can remain until the process runs its course.

System automatically adjusts the laser and substrate plate

Automation also makes for more reliable 3D printing, as demonstrated by the TruPrint 5000's scanner monitoring and leveling system. It ensures that the three laser beams are properly aligned. To this end, the developers provided the recoater with a calibration target that measures the laser beams' positions and sends the coordinates to a software program. The leveling monitor checks the substrate plate's position. It uses a camera and laser sensor system to gauge the height and orientation when setting up a build job. In the event of any deviation, the operator can adjust the substrate plate to the measuring system's specifications.

Monitoring solutions check the quality after every shift

Industrial mass manufacturing requires automated quality assurance solutions. A flaw such as a tiny furrow or a foreign object in the powder bed will corrupt the printed component. To prevent that, TRUMPF developed several processes to assure the quality of components during printing, one of which is powder bed monitoring. A high-resolution camera in the printer takes a picture of the powder bed after each shift and sends this image to an IT system. It assesses images in real time, detects flaws, and automatically notifies the machine operator. "The images can also serve to analyze faults and sustainably improve the process," says Baur. This IT system also categorizes the fault and provides details to help engineers correct the problem.

At the Formnext fair, TRUMPF experts will also demonstrate how melt pool monitoring tech helps assure quality. The melt pool is a very sensitive part of the process. Even minor fluctuations - for example, in the build chamber's temperature or the powder's composition - can lead to flaws. Diodes in the printer capture the light emitted during the process to monitor the melt pool's quality. The IT system then compares these values with data sourced from a reference component, and graphically displays anomalies such as a cooler or overheated melt pool. The machine operator can see the flaw straightaway and halt the process. This assessment takes place after each coat is applied, as does a similar assessment for powder bed monitoring.