Supfina Grieshaber

Productos

Solutions and Services for High Precision Abrasive Machining

Rectificadoras de superacabado

RacePro

|

Rectificadora de superacabado

Supfina Grieshaber GmbH & Co. KG

Rectificadoras de superacabado

Incluso los anillos de rodamientos de rodillos más grandes requieren un superacabado de las pistas de rodadura para soportar las elevadas cargas. La Supfina RacePro está especialmente diseñada para el superacabado flexible de grandes anillos. La máquina está diseñada de tal forma que se puede cargar con una grúa desde arriba o mediante un transportador de rodillos desde la parte delantera y trasera.

Los anillos interiores y exteriores de los rodamientos de rodillos grandes se requieren en una amplia variedad de áreas, tales como:

- Turbinas eólicas

- Sistemas de grúas

- Helicópteros Translated with DeepL

Los anillos interiores y exteriores de los rodamientos de rodillos grandes se requieren en una amplia variedad de áreas, tales como:

- Turbinas eólicas

- Sistemas de grúas

- Helicópteros Translated with DeepL

Superfinish für Laufbahnen von Wälzlagern

|

Rectificadora de superacabado

Supfina Grieshaber GmbH & Co. KG

Rectificadoras de superacabado

Flexibilidad, fiabilidad, seguridad y la más alta calidad de mecanizado han sido durante mucho tiempo los valores de las máquinas Supfina Race, RacePro y RaceFlex

La serie Supfina RaceNeo combina estos valores con la demanda de la más alta calidad de mecanizado y, al mismo tiempo, cumple con los crecientes requisitos en términos de eficiencia económica en la producción en serie de rodamientos de rodillos.

Está optimizada para los requisitos de alta productividad y, al mismo tiempo, consigue los mejores resultados de calidad, tiempos de mecanizado rápidos y alta fiabilidad.

La serie Supfina RaceNeo combina estos valores con la demanda de la más alta calidad de mecanizado y, al mismo tiempo, cumple con los crecientes requisitos en términos de eficiencia económica en la producción en serie de rodamientos de rodillos.

Está optimizada para los requisitos de alta productividad y, al mismo tiempo, consigue los mejores resultados de calidad, tiempos de mecanizado rápidos y alta fiabilidad.

- Tiempos no productivos más rápidos y carga segura .

- Gracias al robot integrado .

- Menor necesidad de espacio y diseño compacto .

- Fácil integración en líneas de producción automatizadas .

- Adaptación modular de la aceptación de piezas .

- Componentes básicos probados .

Supfina Anbaugeräte

|

Rectificadora de superacabado

Supfina Grieshaber GmbH & Co. KG

Rectificadoras de superacabado

Aumente la eficiencia de su máquina de corte

Para obtener la máxima calidad de superficie, nuestros accesorios Superfinish pueden instalarse fácilmente en sus máquinas de rectificado y torneado. De este modo, podrá ofrecer a sus clientes posibilidades completamente nuevas y aumentar su competitividad.

Estaremos encantados de asesorarle y elaborar procesos específicos para su aplicación: desde el accesorio hasta las bandas o piedras de amolar adecuadas, pasando por los parámetros de proceso precisos.

Para obtener la máxima calidad de superficie, nuestros accesorios Superfinish pueden instalarse fácilmente en sus máquinas de rectificado y torneado. De este modo, podrá ofrecer a sus clientes posibilidades completamente nuevas y aumentar su competitividad.

Estaremos encantados de asesorarle y elaborar procesos específicos para su aplicación: desde el accesorio hasta las bandas o piedras de amolar adecuadas, pasando por los parámetros de proceso precisos.

- Amplia gama de accesorios .

- Accesorios de piedra, cinta e híbridos .

- Acoplamiento a máquinas CNC, rectificadoras o tornos existentes .

- Flexible y de aplicación universal .

- Tecnología madura y probada .

- Bajos costes de inversión

- Alta eficiencia económica

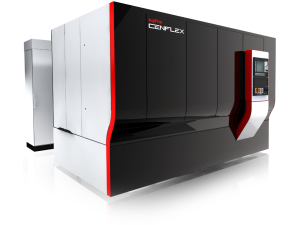

Supfina CenFlex1

|

Superfinishing machine

Supfina Grieshaber GmbH & Co. KG

Rectificadoras de superacabado

Whether it is a limited production of prototypes or a production of flexible production lines, the Supfina CenFlex covers all areas of application with its high reliability and economic efficiency. Depending on the application the set-up is either a one- or multi-step machining process of the workpiece (for example a crankshaft) or a step by step process of a cam- and crankshaft on the same machine (for example motorsports components). Workpieces: - main bearings - pin bearings - post end - flange - thrust face - radii - cam lobes

Supfina Nano

|

Flatfinishing machine for machining planet wheels for automatic transmissions

Supfina Grieshaber GmbH & Co. KG

Rectificadoras de superacabado

The Supfina Nano machine series with a new machine design covers a wide range of flat finish processing needs. Components from the fields of injection technology, transmission components, hydraulic or engine parts can be produced with the tightest tolerances in the tenth micrometer range and with highest reliability and efficiency. Ease of use and very low space requirement at low investment costs are the convincing advantages. The Supfina Nano has been designed for flat finishing of sealing surfaces of injection components such as holding elements, nozzles or valve plates. Planetary gears are examples of the kinds of gear components that can be processed with this tool. The Supfina Nano is suitable for everything from small batch production (e.g. the creation of prototypes) to series production in flexible production lines, covering the entire range of applications and always offering optimal reliability and efficiency. Depending on the intended use, it is possible to integrate a number of different clamping systems into a single machine. Optimal accessibility allows tools to be changed quickly, minimizing changeover time but still ensuring optimal production tolerances.

Supfina R-Cell

|

Rectificadora de superacabado

Supfina Grieshaber GmbH & Co. KG

Rectificadoras de superacabado

¿Busca una solución flexible, modular y económica para las superficies de alta precisión? Con la Célula R, Supfina presenta una innovadora célula de fabricación que cumple fácilmente todos estos requisitos. En la celda robótica modular se puede disponer un gran número de componentes según las necesidades individuales y, gracias a su diseño flexible, se puede ampliar o adaptar en cualquier momento. Esto no sólo asegura una mayor libertad y tiempos de respuesta más rápidos, sino también un gran potencial de ahorro gracias a una producción eficiente en un espacio reducido. Desde el asesoramiento, la planificación, la implementación y la programación hasta la puesta en marcha y el servicio - Supfina le acompaña como proveedor de soluciones integradas en el camino hacia el futuro de la producción. Translated with DeepL

Supfina Race 705-715

|

Superfinishing machine

Supfina Grieshaber GmbH & Co. KG

Rectificadoras de superacabado

The Supfina Race 705 and Race 715 are designed for the Superfinishing operation on raceways of roller bearing inner and outer rings up to 160 mm in diameter. The track record and benefits of the well established Supfina 725 for larger ring diameters have been converted into this newly developed machine concept. The Race 705 and Race 715 cater to different diameter ranges. While the Supfina Race 705 can machine rings of up to 90 mm diameter, the Race 715 covers a range of up to 160 mm. Workpieces: - Cylindrical roller bearings - Tapered roller bearings - Needle roller bearings

Supfina Race 707-717

|

Superfinishing machine

Supfina Grieshaber GmbH & Co. KG

Rectificadoras de superacabado

The innovative Supfina Race 707 and Race 717 are setting new standards in Superfinishing ball bearing inner and outer rings. Both have been optimized to meet the highest productivity demands, while achieving best quality results, fast set-up times and superior reliability. Valuable input from our customers, combined with extensive experience of the Supfina 727 machine types for the large diameter range, are the cornerstones of this newly developed machine concept. The Race 707 and Race 717 cater to different diameter ranges. While the Supfina Race 707 can machine rings of up to 90 mm diameter, the Race 717 covers a range of up to 180 mm. Workpieces: - Deep groove ball bearing - Angular contact ball bearing - Spherical roller bearing - Wheel bearing

Supfina RollerFlex

|

Rectificadora de superacabado

Supfina Grieshaber GmbH & Co. KG

Rectificadoras de superacabado

En los rodamientos de rodillos a rótula modernos, el aumento de la capacidad de rendimiento y de la capacidad de carga está directamente relacionado con el mantenimiento de los tamaños definidos del relieve superficial.

La altamente productiva Supfina RollerFlex desempeña aquí un papel decisivo y es el estándar de la industria para el mecanizado de ranura simple de superacabado de rodillos cilíndricos, cónicos y de barril.

La altamente productiva Supfina RollerFlex desempeña aquí un papel decisivo y es el estándar de la industria para el mecanizado de ranura simple de superacabado de rodillos cilíndricos, cónicos y de barril.

- Rodillos de barril

- Rodillos cilíndricos

- Rodillos cilíndricos

- Rodillos cónicos

- Rodillos cónicos

Supfina Face

|

Rectificadora de superacabado

Supfina Grieshaber GmbH & Co. KG

Rectificadoras de superacabado

With its Face series, Supfina provides the ultimate solution for versatile flat finishing for medium and large workpiece volumes. It’s fast and flexible. Parts from all of these fields – injection technology, transmissions, hydraulics, engines – can be finished with the tightest tolerances in the tenth-micron range, and with the highest reliability and efficiency. As an optional component, Supfina offers a flexible, integrated solution for fully automated mass production. This complete solution from a single source is perfectly in tune with the Face machine’s design. Flat finishing Uniquely flexible

Supfina LCM

|

Versatile production machine for small runs

Supfina Grieshaber GmbH & Co. KG

Rectificadoras de superacabado

With its new LeanCostMachine, Supfina offers versatility of the highest level for superfinishing small and medium-size runs ? economically and flexibly. This extremely versatile modular system, fitted out with state-of-the-art machine technology, meets the highest standards of quality and process dependability, in particular in such fields as the automotive industry, OEM suppliers, the hydraulics and aerospace industries, power generation and medical technology. The Supfina LeanCostMachine® can be equipped with ready-assembled modules designed to match specific machining tasks. Whether fixed in place, manually adjustable or NC controlled, as many as six Supfina attachments for stone and tape finishing can be used at the same time as brushing and polishing attachments. Thanks to the unique design of this installation, all the modules can be integrated into the machine with no further effort. In developing this sophisticated design, not only the best possible configuration of the various Supfina attachments was taken into account, but all the additional machine assemblies such as the switch cabinet, safety cover, attachment mount and operating panel can all be fitted to ready-made holders or bolted to predefined places to suit the current needs. The machine itself can be freely configured to match the installation conditions on-site and the workpiece feed. Consistent standardization of all the assemblies ensures short delivery times, easy expansion and the highest quality in terms of machine construction and products finished. Supfina LeanCostMachine® affordable, versatile and fit for the future.