Spreitzer

Productos

Máquinas y equipos para sellado y marcado

Endlos-Stangen-Signiermaschine ESS 70

|

Máquina y equipo para sellado y marcado

Spreitzer GmbH & Co. KG

Máquinas y equipos para sellado y marcado

| 1-70 mm (1-90 mm) | |

| 16,5 m/min | |

| Ø 72/30×20 mm | |

| 75 mm | |

| 0,37 KW-0,5 PS | |

| 49 Nm | |

| 73 min-1 | |

| 400 V – 50 Hz | |

| 1,1 A | |

| IP 44 |

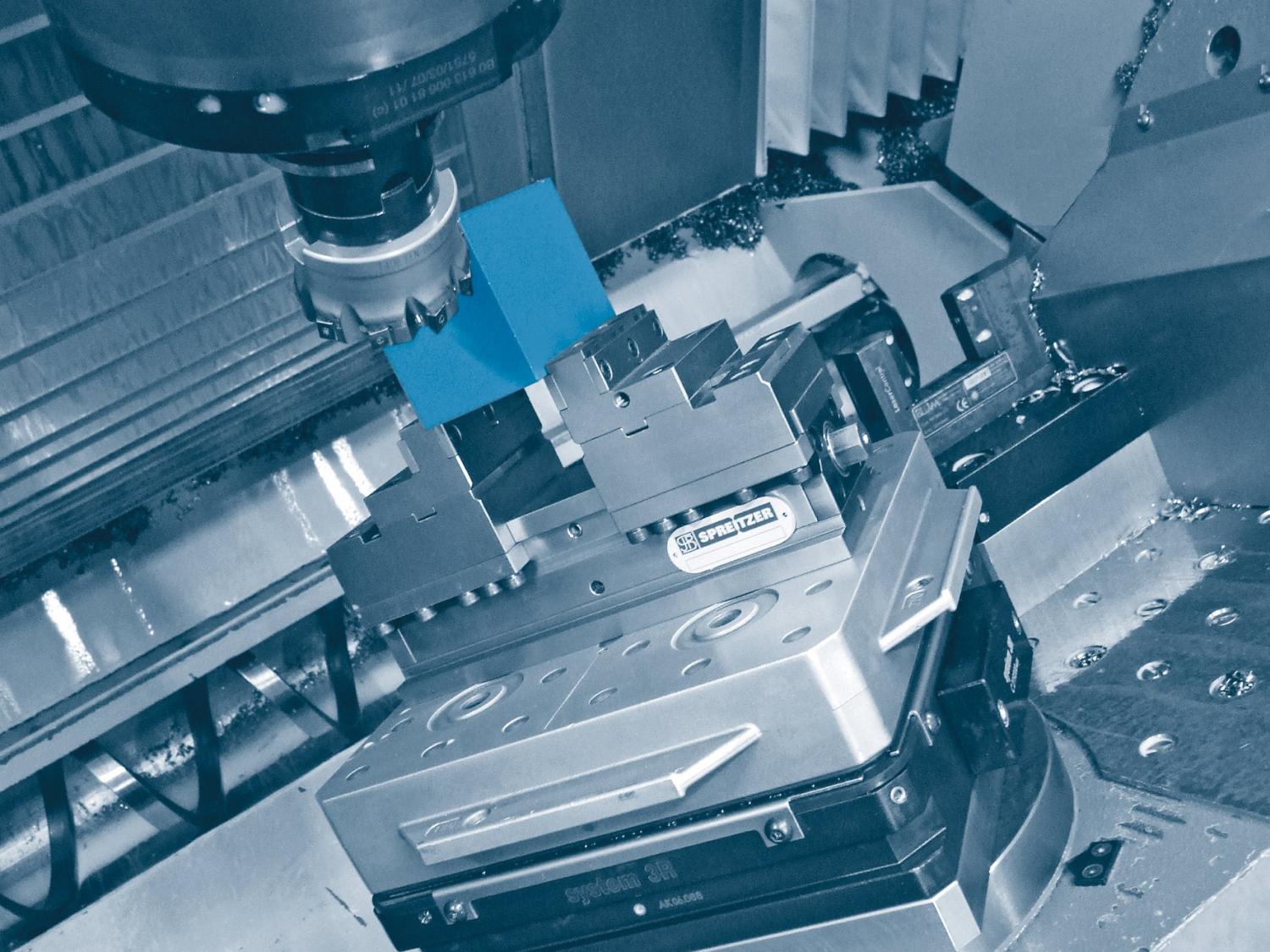

The SPREITZER bar-marking-machine makes quality traceable. Prior to the machining the material charge will get a product based or customer based marking.

Therefore, the quality of the product can be retracted during the whole life cycle of the product. Each turned part leaves the production line marked.

Construction and function of the machine:

The roller bearing spindle, the detachable counter bearing, the adjustable pressing roll as well as the horizontal and vertical guide rolls built in a robust GG 25 machine body. The spindle is driven by a robust gear motor with a 1:20 reduction. The exchageable marking rollers are friction-locked mounted on the spindle. Through a additional counter earing the blocking is certainly absorbed. The pressing roll is mounted inside a sleeve which is adjusted using lead screw and handwheel.