Spreitzer

Productos

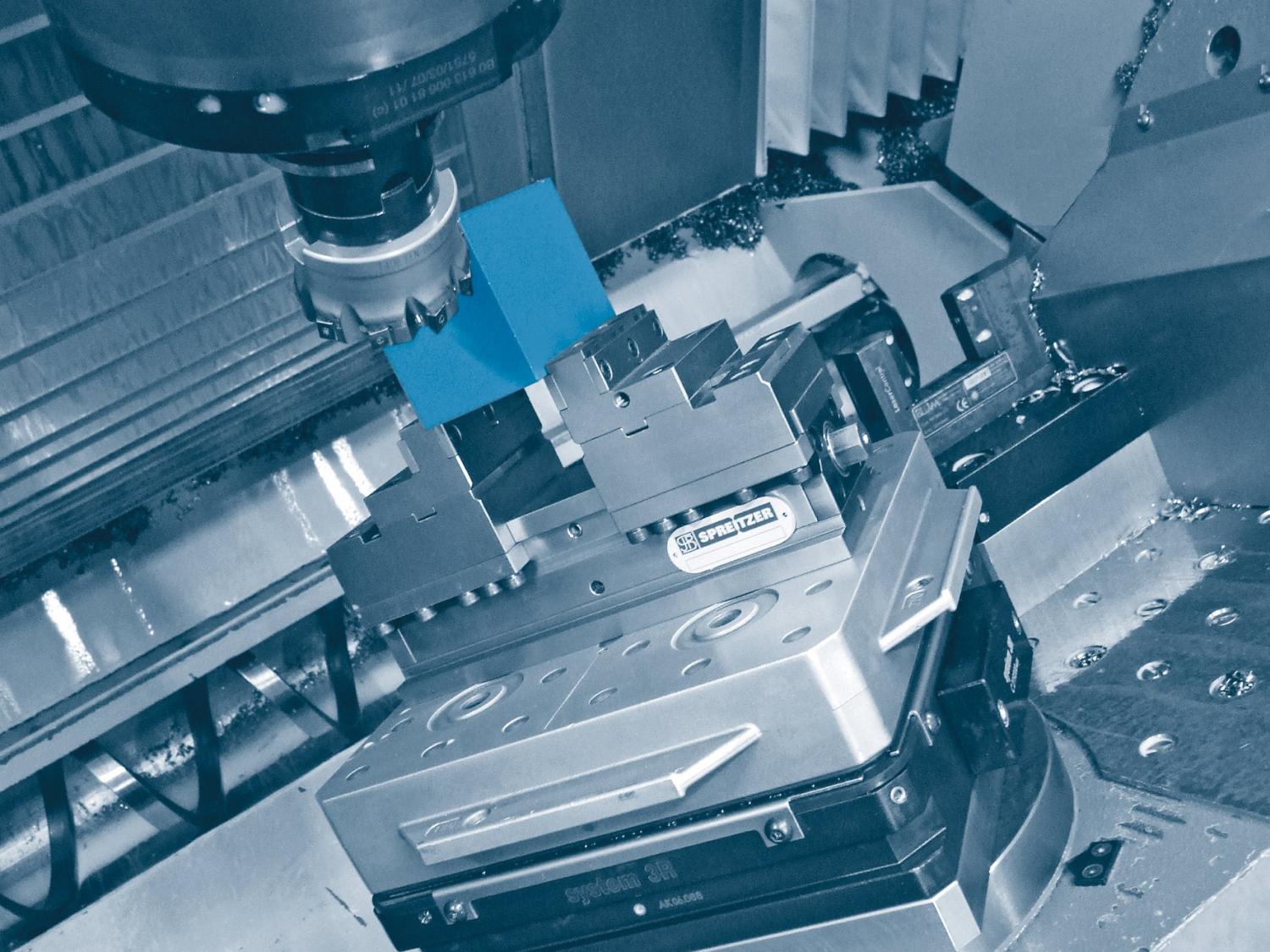

Máquinas-herramienta

Máquinas transfer para la producción y unidades de mecanizado

Präzisions-Dreheinheit PDE

|

Unidad de torneado

Spreitzer GmbH & Co. KG

Unidades de torneado

With the use of the precision rotary unit PDE cylindrical workpieces with a diameter up to 134 mm can be rotated with high accuracy.

The mounting can be done in horizontal or vertical position on the base plate.

The precision rotary unit can be ordered without base plate and without three-jaw chuck.

Version:

- For individual testings, serial testings with optional accessories possible

- Precision rotary unit horizontally and vertically mountable

- Material: steel, rust-resistant, aluminium

- Finish precision grinded, hard coated

- Three-jaw chuck DBF 100 VA, rust-resistant, 100 mm diameter (repetition accuracy 0,005 mm)

or three-jaw chuck DBF 140 VA, rust-resistant, 140 mm diameter (repetition accuracy 0,005 mm)

Präzisions-Dreheinheit PDE micro

|

Unidad de torneado

Spreitzer GmbH & Co. KG

Unidades de torneado

Thanks to its compact design, the precision rotary unit PDE micro is particularly suitable for the use on measuring microscopes and optical coordinate measuring machines from different manufacturers.

The mounting holes in the base plate offer universal mounting possibilities. The precision rotary unit is horizontally mountable and via angle plate 90° also vertically mountable. It has a 15° indexing, interim indexing positions by 360° scale and nonius. The three-jaw chuck DBF 34 VA (34 mm diameter) has a repetition accuracy of 0,005 mm.

Version:

- Horizontally and vertically mountable

- Material: steel, rust-resistant, aluminium

- Finish precision grinded, hard coated

- Three-jaw chuck DBF 34 VA, rust-resistant, 34 mm diameter (repetition accuracy 0,005 mm)

15° indexing, interim indexing positions by 360°-scale and nonius

Máquinas para marcado

Endlos-Stangen-Signiermaschine ESS 70

|

Máquina y equipo para sellado y marcado

Spreitzer GmbH & Co. KG

Máquinas y equipos para sellado y marcado

| 1-70 mm (1-90 mm) | |

| 16,5 m/min | |

| Ø 72/30×20 mm | |

| 75 mm | |

| 0,37 KW-0,5 PS | |

| 49 Nm | |

| 73 min-1 | |

| 400 V – 50 Hz | |

| 1,1 A | |

| IP 44 |

The SPREITZER bar-marking-machine makes quality traceable. Prior to the machining the material charge will get a product based or customer based marking.

Therefore, the quality of the product can be retracted during the whole life cycle of the product. Each turned part leaves the production line marked.

Construction and function of the machine:

The roller bearing spindle, the detachable counter bearing, the adjustable pressing roll as well as the horizontal and vertical guide rolls built in a robust GG 25 machine body. The spindle is driven by a robust gear motor with a 1:20 reduction. The exchageable marking rollers are friction-locked mounted on the spindle. Through a additional counter earing the blocking is certainly absorbed. The pressing roll is mounted inside a sleeve which is adjusted using lead screw and handwheel.