Spreitzer

Productos

Herramientas de precisión

Mordazas

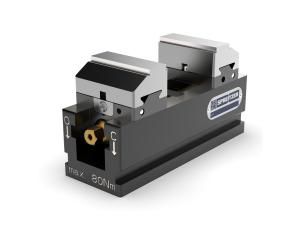

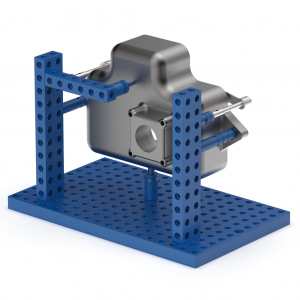

Mechanische Zentrischspanner MZS

|

Tornillo de banco

Spreitzer GmbH & Co. KG

Tornillos de banco

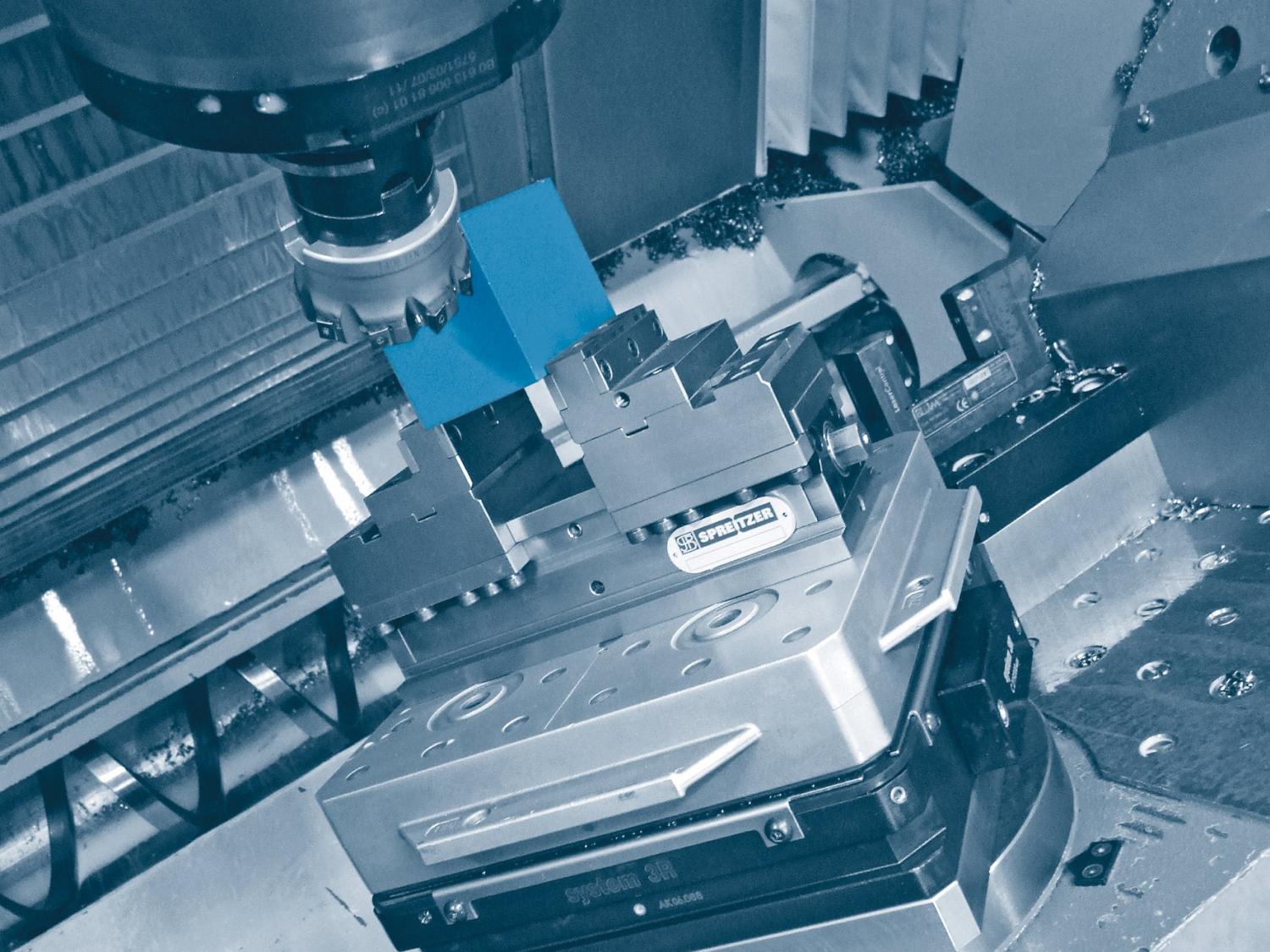

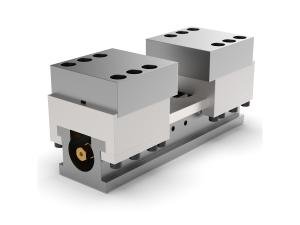

The large product variety and the high centering and repetition accuracy make this centre-clamping vise series a universal clamping solution especially for already premachined workpieces or precision parts.

The high rigidity of the vise body as well as the optimal guide ways of the guide jaws allow high clamping accuracy.

Version:

- Hardened and grinded spindle

- Material: modified steel, surface hardened

- Functional surface precision grinded

- Semi encapsulated, two-sided chip flow

- Centering accuracy ± 0,005 mm

- Repetition accuracy 0,003 mm

- Pairing accuracy 0,01 mm

Mechanischer Doppelschraubstock MDS

|

Tornillo de banco

Spreitzer GmbH & Co. KG

Tornillos de banco

Double vise MDS with fixed center jaw for precise machining of two workpieces to a defined fixed stop.

The double vise has an optimized, compact design and enables first and second operation in high quality.

Workpieces with different lengths up to 3 mm can be securely clamped.

Features:

- Material: modified steel surface hardened

- Functional surface precision grinded

- Hardened and grounded spindle

- Ground-in and clearance-free adjusted base jaws

- 100% encapsulated design

- Highest repetition accuracy

- Pairing accuracy 0,01 mm

Mechanischer Kompaktspanner MSU

|

Tornillo de banco

Spreitzer GmbH & Co. KG

Tornillos de banco

The mechanical compact vise MSU allow secure and precise clamping of workpieces to the defined fixed stop.

The extensive jaw program of reversible top jaws provides maximum flexibility and optimum accessibility especially on multi-axis machining centers.

The fixed jaws can be mounted on the vise body at two positions. Due to the variable step form of the reversible top jaws, a maximum clamping range can be covered.

Features:

- Compact design, maximum accessibility

- Wide clamping range by reversible top jaws

- Highest flexibility

- Material: modified steel, surface hardened

- Finish: functional surface precision grinded

- Ground-in base jaws

- Hardened spindle

- Pairing accuracy 0,02 mm

Mechanischer Rohteilspanner RS

|

Tornillo de banco

Spreitzer GmbH & Co. KG

Tornillos de banco

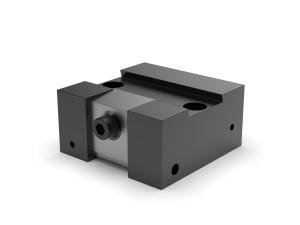

Mechanical raw part clamping unit RS are used on 5- and multi-axis machines.

You get a maximum degree of liberty due to the small dimension in combination with palletizing systems.

A maximum clamping force is attained by the back cut in the fix jaw and the clamping jaw.

An additional slot stone can be used for axial positioning.

Features:

- Small disturbance range

- Maximum access

- Material: steel

- Finish: hardened, black-finished

- Only 3 ? 5 mm clamping depth necessary

- Clamping from outside to inside (external clamping)

- Pairing accuracy 0,02 mm

Mechanischer Zentrischspanner MZC

|

Tornillo de banco

Spreitzer GmbH & Co. KG

Tornillos de banco

The self-centering clamping vise MZC is characterized by an encapsulated, massive and torsion-free construction. The cleaning effort resp. malfunction because of dirt and stuck chips will be minimized.

The large clamping width and the high clamping force enable the universal and flexible use on multi-axis machining centres.

Features:

- Massive and torsion-free, 100% encapsulated

- High clamping force

- Large clamping width

- Maximum access

- Wide range of clamping jaw types

- Usage on automation solutions

- First and second clamping

- For unmachined and pre-machined workpieces

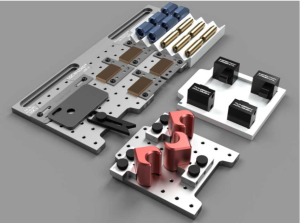

Mehrfachspannsystem MSE

|

Tornillo de banco

Spreitzer GmbH & Co. KG

Tornillos de banco

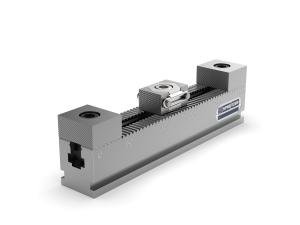

The multiple clamping system MSE allows positioning and clamping of two or more workpieces at the same time.

By using a number of clamping elements in a longitudinal and diagonal direction the work area can be used more efficiently.

The compact construction allows an economic application on palletizing and automation systems.

Features:

- Clamping of two workpieces against fixed stop

- Clamping from outside to inside (external clamping)

- Modular combinable

- Clamping jaws with pull-down effect

- Material: modified steel

- Finish: hardened, black-finished

- Functional surface precision grinded

- 1 Pair of clamping jaws included

- Pairing accuracy 0,02 mm

Pneumatischer Kompaktspanner PS

|

Tornillo de banco

Spreitzer GmbH & Co. KG

Tornillos de banco

Clamping against a fixed jaw.

Due to the pneumatic operation of this vise series the clamping process can be shortened or completely automated by the use of industrial robots.

Features:

- Short clamping time

- High clamping accuracy

- Built-in version upon request

- Material: modified steel surface hardened

- Finish: functional surface precision grinded

- Ground-in and clearance-free adjusted base jaws

- Repetition accuracy 0,003 mm

- Pairing accuracy 0,01 mm

Pneumatischer Zentrischspanner PZS²

|

Tornillo de banco

Spreitzer GmbH & Co. KG

Tornillos de banco

Due to the pneumatic operation of this centre-clamping vise series the clamping process can be shortened or completely automated by the use of industrial robots.

Features:

- Short clamping time

- Usable for automation

- High clamping accuracy

- Assembly units upon request

- Material: modified steel surface hardened

- Functional surface precision grinded

- Ground-in and clearance-free adjusted base jaws

- Centering accuracy ±0,005 mm

- Repetition accuracy 0,003 mm

- Pairing accuracy 0,01 mm

Präzisions-Schraubstock SP

|

Tornillo de banco

Spreitzer GmbH & Co. KG

Tornillos de banco

The precision vice SP is rust-resisdant and designed for the universal use in the measuring and control room or for small machining tasks.

Type VA:

- Operation: mechanical

- Material: magnetizable chrome steel, rust-resistant

- Finish: completely hardened, completely precision

- Square-accuracy: 0.005 mm

- Parallel-accuracy: 0.003 mm

- Aluminium version with hardened universal jaws available

Mechanischer Zentrischspanner MZE

|

Tornillo de banco

Spreitzer GmbH & Co. KG

Tornillos de banco

The centre-clamping vise MZE is used always when maximum centre and repetition precision are not necessary.

It is especially designed for raw material clamping or on unmachined part machining on multi-axis machining centres and is used as an economic centre-clamping vise solution for work on pallets or automation systems.

Features:

- Maximum access and wide clamping range

- Suitable for external and internal clamping

- Interchangeable clamping jaws

- Material: modified steel, surface hardened

- Functional surface precision grinded

- Hardened spindle

- Ground-in base jaws

- Centering accuracy ±0,015 mm

- Repetition accuracy 0.01 mm

- Pairing accuracy 0,02 mm

Mechanischer Zentrischspanner MZQ

|

Tornillo de banco

Spreitzer GmbH & Co. KG

Tornillos de banco

The centre-clamping vise series MZQ with quick change jaws enables replacement of the jaws within seconds.

They are designed specifically for use within pallet automation and for several times a day retooling the centre-clamping vises.

The reversible stepped jaws allow maximum accessibility even with short cutting tools.

Due to the stepped form of the reversible top jaws, the complete clamping range can be covered.

- Large clamping range due to reversible top jaws

- Material: modified steel, surface hardened

- Functional surfaces precision grinded

- Hardened spindle

- Ground-in base jaws

- Centering accuracy ± 0,015 mm

- Repetition accuracy 0,01 mm

- Pairing accuracy 0,02 mm

Mechanischer Zentrischspanner MZU

|

Tornillo de banco

Spreitzer GmbH & Co. KG

Tornillos de banco

The centre-clamping vise MZU with reversible step jaws gives the user the highest level of flexibility on multi-axis machining centres.

The tiered step jaws offer maximum accessibility, even for short cutting tools. Furthermore, due to the variable tiered form, all clamping possibilities are covered. The centre-clamping vise type MZU is especially suitable for flexible raw parts clamping.

Features:

- Small disturbance range

- Maximum access

- Large clamping width

- Material: modified steel, surface hardened

- Functional surface precision grinded

- Hardened spindle

- Ground-in base jaws

- Centering accuracy ±0,015 mm

- Repetition accuracy 0.01 mm

- Pairing accuracy 0,02 mm

Mechanischer Zentrischspanner MZR

|

Sistema de sujeción

Spreitzer GmbH & Co. KG

Tornillos de banco

The self-centering vise-series MZR is used as a cost-effective clamping tool for clamping raw parts on multi-axis machining centres.

With its compact, maximum access to the workpiece on multi-axis machining centers is possible.

The clamping width can be enlarged with reversible jaws.

Hydraulische Zentrischspanner HZS

|

Sistema de sujeción

Spreitzer GmbH & Co. KG

Tornillos de banco

Due to the hydraulic operation of this centre-clamping vise series the clamping process can be shortened or completely automated by the use of industrial robots.

For use in 24/7 automation cells we offer a central lubrication system.

The compact and space-saving design allows machining without interfering edges or installation in limited workspaces.

The series are specified for internal and external clamping.

The air purge connection offers protection against the permeation of coolants and dirt.

For maximum accessibility, the version HZS 180-80 A can optionally be manufactured with center bore.

An integrated version of the hydraulic self-centering vise HZA A you will find in our catalogue.

Advantages at a glance

- Short clamping time

- High clamping accuracy

- Material: modified steel surface hardened

- Finish: functional surface precision grinded

- Ground-in and clearance-free adjusted base jaws

- Centering accuracy ±0,005 mm

- Repetition accuracy 0,003 mm

- Pairing accuracy 0,01 mm

Pneumatischer Zentrischspanner PZS

|

Sistema de sujeción

Spreitzer GmbH & Co. KG

Tornillos de banco

Due to the pneumatic operation of this centre-clamping vise series the clamping process can be shortened or completely automated by the use of industrial robots.

The pneumatic centre-clamping vise PZS is also available as an intregrated version. For further information please refer to our cataloque.

Advantages at a glance:

- Short clamping time

- Usable for automation

- High clamping accuracy

- Assembly units upon request

- Material: modified steel, surface hardened

- Functional surface precision grinded

- Ground in and clearance-free adjusted base jaws

- Centering accuracy ±0,005 mm

- Repetition accuracy 0,003 mm

- Pairing accuracy 0,01 mm

Elektromechanischer Zentrischspanner EZC

|

Sistema de sujeción

Spreitzer GmbH & Co. KG

Tornillos de banco

Electromechanical components are more energy efficient than pneumatically or hydraulically operated systems. In the field of workpiece clamping technology electrically driven compressors or aggregates had to generate so far air or oil pressure continuously to hold or clamp workpieces during machining securely.

Pneumatic and hydraulic clamping technology is still justified, however, opportunities are opening with electromechanical systems, which can bring significant advantages to the users.

A central lubrification system for the use in 24/7 automation cells can be offered.

Built-in versions are available upon request.

If necessary, additional purge air offers protection against dirt and coolants.

Advantages at a glance:

- Energy-efficient

- Self-locking

- Integrated sensor system

- Material: modified steel surface hardened,

- Finish: functional surface precision grinded

- Ground-in and clearance-free adjusted base jaws

- Centering accuracy ±0,005 mm

- Repetition accuracy 0,003 mm

- Pairing accuracy 0,01 mm

Winkelschraubstock SPS-2

|

Sistema de sujeción

Spreitzer GmbH & Co. KG

Tornillos de banco

The angle vise SPS-2 is used for accurate machining and inspection of surfaces and angular surfaces. The two-dimensional angle adjustment is done using vernier scale and fine adjustment screw. For size 70 with 3?-vernia, for size 120 with 5?-vernia. Horizontally rotatable up to 360°. Vertically adjustable up to 2 × 60°. Advantages at a glance: - Mechanical operation - Material: tool steel - Finish: hardened, precision grinded - Square-accuracy 0,003 mm - Parallel-accuracy 0,003 mm - Special version with three-jaw chuck upon request

ALUMESS.easyloc Laser Einsteiger-Sets

|

Sistema de sujeción

Spreitzer GmbH & Co. KG

Sistemas de sujeción

Los conjuntos ALUMESS.easyloc para sistemas de marcado por láser son los únicos sistemas de fijación modulares listos para usar, rápidamente intercambiables, para el marcado por láser, el grabado por láser y la soldadura por láser.

Se pueden configurar fácilmente, tanto de forma individual como específica para cada máquina. La regleta de conexión correspondiente se fija al sistema de marcado. Las paletas intercambiables magnéticas y encajables toman las piezas de trabajo mediante elementos de fijación universales.

las piezas de trabajo mediante elementos de fijación universales.

Los conjuntos de arranque ALUMESS.easyloc están disponibles en diferentes versiones:

180- LA Juego de iniciación 180-L + juego de elementos de fijación LA.

Referencia LA SYS60_DKM180LA02

360-LA Juego de iniciación 360-L + juego de dispositivo de sujeción LA

U.E. Código LA SYS60_DKM360LA02

540-LA Conjunto de arranque 540-L + dispositivo de sujeción LA

U.E. Código LA SYS60_DKM540LA02

720-LA Conjunto de arranque 720-L + dispositivo de sujeción LA

Código LA SYS60_DKM720LA02

Translated with DeepL

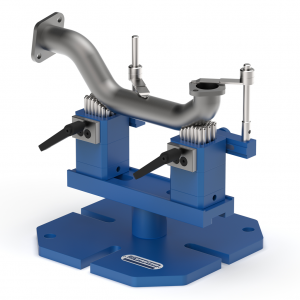

ALUMESS.easyloc Spannsystem für Messmaschinen

|

Sistema de sujeción

Spreitzer GmbH & Co. KG

Sistemas de sujeción

El sistema de sujeción ALUMESS.easyloc consiste en paletas intercambiables combinables modularmente y fáciles de instalar, que se encajan magnéticamente.

Las soluciones de fijación son rápidamente intercambiables, por lo que se puede acelerar el proceso de medición y aumentar la cantidad de producción por turno.

Ventajas del sistema:

- Fácil de usar

- Para la luz incidente y transmitida

- Combinable de forma modular

- Paletizable

- Los dispositivos existentes se pueden adaptar fácilmente

- Posibilidad de sujeción múltiple por máquina de medición

Aplicación principal:

- Medición óptica y táctil

- Medición individual y en serie

- Máquinas ópticas de medición de coordenadas y proyectores de medición

Translated with DeepL

ALUMESS.junior Spannsystem für Messmaschinen

|

Sistema de sujeción

Spreitzer GmbH & Co. KG

Sistemas de sujeción

El sistema de sujeción ALUMESS.junior ofrece una introducción sencilla y económica a la tecnología de sujeción modular para la medición en serie en máquinas de medición de coordenadas táctiles.

Dependiendo de la aplicación, se pueden montar de forma flexible y rápida diferentes elementos de soporte y posicionamiento, así como los elementos de sujeción necesarios, en las paletas, que están equipadas exclusivamente con roscas de sujeción. Las opciones de montaje de los componentes están diseñadas para ser lógicas y fáciles de usar.

Ventajas del sistema:

- Fácil de usar

- Precios razonables

- Flexible

- Paletizable

Aplicación principal:

-Medición táctil

- Medición en serie

- Sistema básico de bajo coste para máquinas de medición de coordenadas

Translated with DeepL

ALUMESS.maxx Spannsystem für Messmaschinen

|

Sistema de sujeción

Spreitzer GmbH & Co. KG

Sistemas de sujeción

El sistema de sujeción ALUMESS.maxx está diseñado principalmente para su uso en máquinas de medición de coordenadas táctiles.

Otros ámbitos de aplicación son la construcción de muestras y prototipos, el marcado por láser, el mecanizado por láser y el uso como dispositivo de montaje.

Los orificios de posicionamiento y las roscas de fijación en las paletas, placas, listones y soportes, así como una amplia gama de elementos de soporte, posicionamiento y tope, permiten una posición precisa,

montaje reproducible y estable de cada dispositivo de sujeción.

Debido a la máxima reproducibilidad de los dispositivos de sujeción, sólo es necesario almacenar los elementos específicos de la pieza para su posterior reutilización.

Ventajas del sistema:

- Muy robusto y duradero

- Máxima universalidad

- Patrón de agujeros continuo

- Paletizable

Aplicación principal:

- Medición táctil

- Medición en serie

- Uso universal en máquinas de medición de coordenadas

Translated with DeepL

ALUMESS ? Spannvorrichtungen für Messmaschinen

|

Sistema de sujeción

Spreitzer GmbH & Co. KG

Sistemas de sujeción

Modular clamping fixtures for measuring machines, coordinate measuring machines

The ALUMESS fixturing system is a highly flexible and wide-ranging modular construction system for fixturing workpieces on measuring machines.

The clamping system is based upon perforated plates on which several clamping elements, clamping devices can be positioned. These perforated plates can be screwed onto the measuring plates of the measuring machines.

ALUMESS clamping solutions enable precise and reproducible setups of clamping devices for different workpieces of all industries. They are designed for the flexible use at the measuring station, on coordinate measuring machines as well as on optical measuring systems.

The ALUMESS clamping system is available in 4 different versions:

ALUMESS.basic

ALUMESS.junior

ALUMESS.maxx

ALUMESS.optic

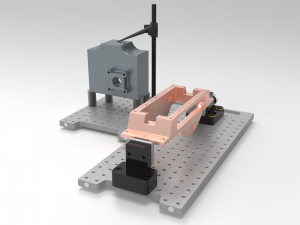

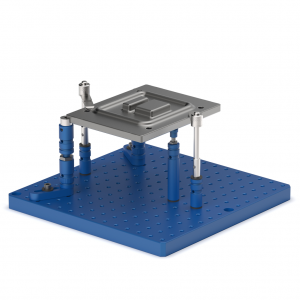

Nullpunktspannsystem MZP

|

Sistema de sujeción

Spreitzer GmbH & Co. KG

Sistemas de sujeción

With the mechanical zero-point-system MZP clamping devices like centre-clamping vises, self-centering vises, machine vises can be rapidly changed on the base unit.

The zero-point-clamping-system enables an increase in machine run-time and manufacturing quality.

The change of the clamping devices is done only by a central clamping screw.

Due to the flat design and the fixturing holes of the zero-point-system an universal mounting on the machine table or on fixturing devices is possible.

Advantages at a glance:

Quick set-up, conversion

Precise positioning 0.005 / 0.01 mm (depending on version)

Clamping tools and pallets can be indexed through 4 × 90°

High pull-in force, high holding force

Economic system

Our zero-point-system:

4-point clamping unit MZP

Interchangeable pallet WP

Clamping unit MZP with indexing

Chucking spigot

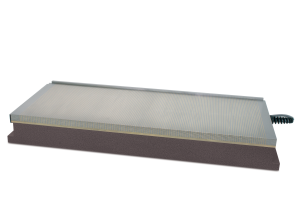

Permanent Magnetspannplatte SPEF

|

Placa de sujeción magnéticas

Spreitzer GmbH & Co. KG

Placas de sujeción magnéticas

The permanent magnetic clamping plate SPEF is a high precision plate for use on eroding machines and everywhere where the magnetic field should only be directly on the plate.

Magnetic chuck SPEF works with a strong, scatter-resistant ceramic-magnetic system, which creates a field height below 3mm. The clamping force can be changed stagelessly in 2 sectors, the plate is silver brazed and therefore very robust and stiffy. The clamping plate is operated by a removeable Allen key.

Finish:

- Ceramic-magnetic system

- Aluminium body

- Pole pitch 2 + 1.5 + 6 mm

- Nominal holding force 70 N/cm²

- Magnetic field height 2-3 mm

- Pole plate wearing limit 5 mm

Cargando...