Mercado de máquinas e instalaciones usadas

Máquinas usadas Water jet cutting systems

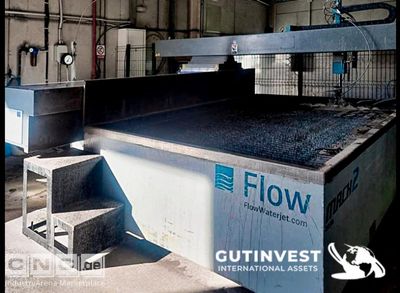

Waterjet cutting equipment is a type of cutting tool that uses water jets to cut materials. Waterjet cutting equipment uses a high pressure water jet forced through a nozzle to cut materials such as metals, plastics, stone and wood. Waterjet cutting systems typically work by using computer-controlled systems that can cut the material into a specific shape. Most waterjet cutting systems can make precise cuts with an accuracy of up to 0.1 mm. A waterjet cutting system can also mix abrasive materials such as abrasives or granules into the waterjet to facilitate the cutting of hard materials such as stone, ceramics or metal. The abrasive material is typically stored in a separate container and pumped through the nozzle during the cutting process. Waterjet cutting equipment offers several advantages, including high cut quality and precision, the ability to cut a variety of materials, and low heat generation during the cutting process, which reduces the risk of material deformation or discoloration. In addition, it is environmentally friendly and does not require toxic or hazardous chemicals. Waterjet cutting equipment is used in a variety of industries, including automotive, aerospace, machinery, advertising signage, stone, ceramics, and food.

|

|

|

|

|

|