Mercado de máquinas e instalaciones usadas

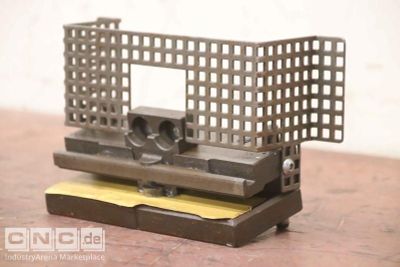

Máquinas usadas Hole punch

Hole punching is a process used to cut holes in materials such as metal, plastic or paper. It is one of the most common methods for creating holes in metal plates, sheets, tubes and profiles. The hole punching machine usually works with a punch and die combination. The punch component is a sharp, round or multi-edged tip that punches the hole through the material. The die component is a type of mold that holds the material and guides the punch tip to punch the hole. The machine can be operated by manual power or by hydraulic or pneumatic power driven by a motor. The machine performs a series of punching operations to cut holes of different sizes and shapes in the material. Hole punching offers several advantages, including the ability to cut holes of various sizes and shapes quickly and accurately. It is also cost-effective and offers high efficiency in producing large quantities of the same or similar parts. It is suitable for processing various materials such as steel, aluminum, copper and plastic. Hole punching is widely used in many industries, such as automotive, electrical appliance housing manufacturing, aerospace and construction.

|

|

|

|

|

|

|

|

|

|

|

|