Mercado de máquinas e instalaciones usadas

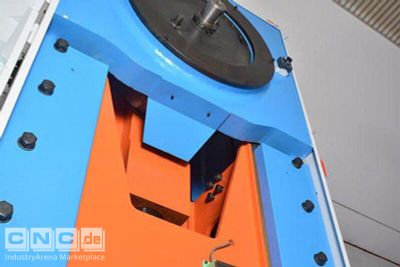

Máquinas usadas Open gap eccentric presses

Single column eccentric presses are a type of mechanical presses that use an eccentric shaft to apply a force to the material being processed. They belong to the group of punch presses and are widely used in metal processing to form, cut or punch sheets, tubes and profiles. As the name implies, single column eccentric presses have a single, vertical column that guides the ram. The ram is attached to the eccentric shaft, which is driven by a motor. When the motor is running, the eccentric shaft rotates and moves the ram up and down. The press table is usually equipped with a die that holds and shapes the material to be processed. Single column eccentric presses have the advantage of offering high precision and accuracy and are very versatile, as they can be used for a variety of applications. They can also reach high speeds and can generate large forces. In addition, they require less space than other types of presses because they have only a single upright. However, single-column eccentric presses also have some disadvantages. They can be noisy and usually require some training to operate them safely and effectively. In addition, their limited stroke length and tonnage capacity may make them unsuitable for some applications.

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|