Mercado de máquinas e instalaciones usadas

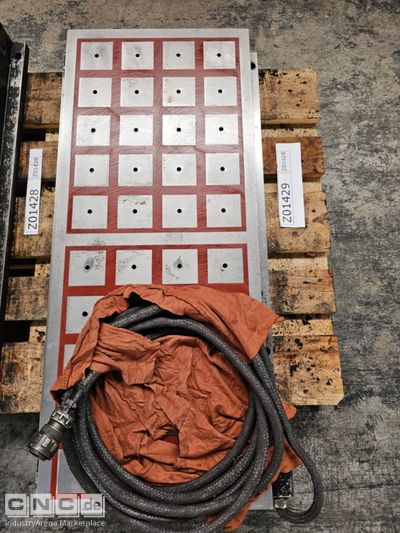

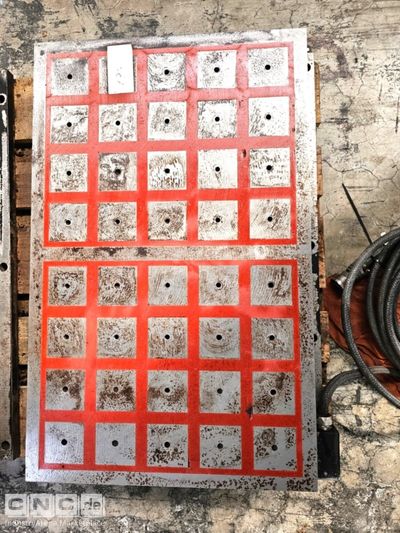

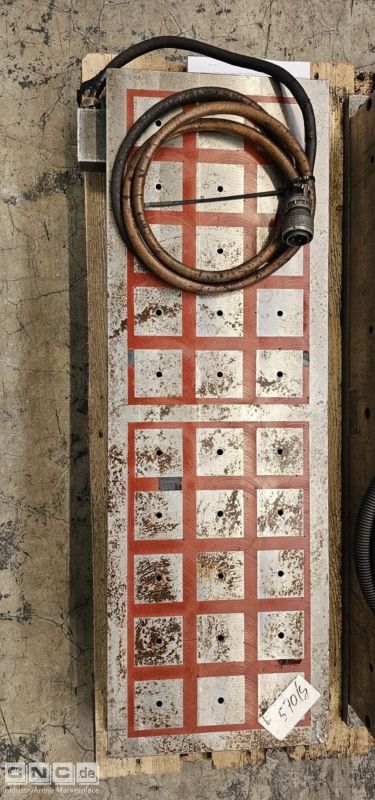

Máquinas usadas Chucks, hydraulic

Hydraulic chucks are clamping devices used to securely and precisely fasten workpieces in a machine tool such as a milling machine or a lathe. Unlike mechanical chucks, hydraulic chucks use a hydraulic compressive force to hold the workpiece in place. The hydraulic chuck consists of a base body and a clamping unit that is hydraulically operated. The base body is usually connected to the spindle head of the machine tool, while the clamping unit contains the workpiece holder. The clamping unit contains a piston and cylinder arrangement that presses the workpiece holder against the workpiece, holding it securely in place. A hydraulic chuck offers several advantages over mechanical chucks. Because the hydraulic chuck operates with a constant hydraulic pressure force, it can securely and uniformly clamp workpieces, regardless of the geometry or size of the workpiece. Hydraulic chucks are also faster and easier to use than mechanical chucks, as they can be operated with a simple push of a button to clamp or release the workpiece. They are also capable of producing higher clamping forces than mechanical chucks, which may be necessary for machining heavy or large workpieces. However, hydraulic chucks are typically more expensive than mechanical chucks and require regular maintenance to ensure that they function properly.

|

|

|

|

|

|

|

|

|