Mercado de máquinas e instalaciones usadas

Máquinas usadas Collet devices

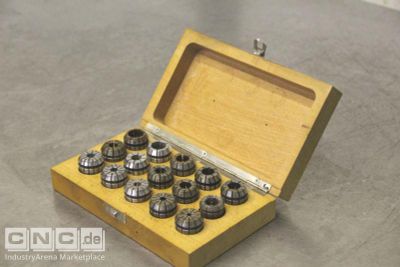

Collet devices are tool holders specially designed for safe and precise clamping of tools in machining centers. They are usually used in lathes and milling machines. A collet device consists of a collet, which holds the tool, and a collet chuck, which exerts the clamping force on the collet. The collet chuck is usually a sleeve that is inserted into the spindle of the machine and holds the collet. The clamping force is transmitted to the collet chuck by tightening a nut, which compresses the collet and holds the tool securely in place. The clamping force is an important factor in the quality of machining, as it ensures that the tool does not slip during the machining process. Collet devices are available in various designs to hold different tools and tool sizes. They are also available in different levels of precision, depending on the requirements of the application. High-precision collet setups can hold very tight tolerances and are often used in aerospace and other demanding industries. Proper handling and maintenance of collet equipment is important to ensure long life and high precision. It is important that the collets and collet chuck are cleaned and inspected regularly to ensure that they are in good condition and that the required clamping force is maintained.

|

|

|

|

|