DATRON AG

Productos

DATRON AG

Fresadoras de alta velocidad (HSC)

CNC-Fräsmaschine MLCube

| Distancia de desplazamiento |

|

| 1520 mm | |

| 1150 mm | |

| 245 mm | |

| Características de la máquina |

|

| 2502 kg | |

The DATRON MLCube is the best choice for cost-effective sheet machining, for example, for the production of front panels, housings, profiles and other aluminium workpieces milled in nested form. Other non-ferrous metals or composite materials can also be processed most efficiently with the MLCube. Its short setup times and its ability to use different clamping techniques simultaneously, its very low power consumption and its excellent price-performance ratio - even for low production volumes - provide long-term and extremely high profitability.

DATRON neo

|

Fresadora de alta velocidad (HSC)

DATRON AG

Fresadoras de alta velocidad (HSC)

| Distancia de desplazamiento |

|

| 520 mm | |

| 420 mm | |

| 220 mm | |

| Características de la máquina |

|

| 740 kg | |

The DATRON neo is setting new standards in terms of quality, process reliability and user-friendliness. With the proven plug & play principle and the intuitive DATRON next software, users can work productively straight away, regardless of their level of experience. The excellent access to the work area makes it very easy to load and set up workpieces. Thanks to the integrated camera and the DATRON 3D probe, workpiece set-up is unmatched in terms of simplicity, speed and precision. The DATRON neo impresses with its high performance and dynamics while remaining extremely compact and versatile.

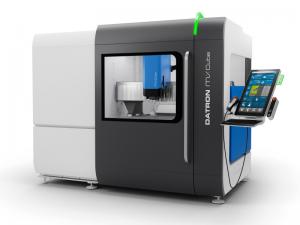

DATRON MXCube

|

Fresadora de alta velocidad (HSC)

DATRON AG

Fresadoras de alta velocidad (HSC)

| Distancia de desplazamiento |

|

| 1040 mm | |

| 850 mm | |

| 270 mm | |

| Características de la máquina |

|

| 3800 kg | |

The rigid structure, maximum dynamics and a powerful high-frequency spindle are ideal for modern HSC strategies and can combine high machining volume with outstanding surface finish. The completely redesigned machine with optimised chip concept offers a wide range of functions for operation in an industrial environment.