Mercado de máquinas e instalaciones usadas

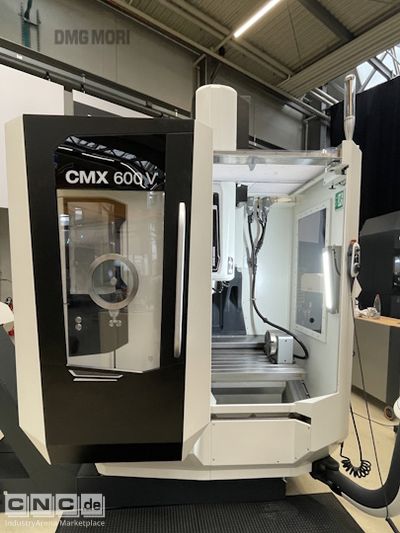

Máquinas usadas Machining centres

Machining centers are computer-controlled machine tools capable of performing a wide range of machining operations such as milling, turning, drilling, grinding and sawing. They are usually equipped with high precision and speed and allow complex geometric shapes to be machined in a single operation. Most machining centers have a movable table on which the workpiece is fixed and one or more tool holders in which various tools such as milling cutters, drills, etc. can be accommodated. They are usually operated with a computerized numerical control (CNC) system that allows precise control of tool position and workpiece movements. Machining centers are used in a wide range of industries, including automotive, aerospace, engineering, electronics, and medical. They are particularly useful for the production of complex geometric shapes and small batches. There are different types of machining centers, such as horizontal machining centers, vertical machining centers, 5-axis machining centers and universal machining centers. Each type has its own advantages and areas of application.

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|