IMS Software

Productos

Postprocesadores

IMSpost

|

Postprocessing software

IMS Software, Inc.

Postprocesadores

IMSpost, the world’s most advanced postprocessing software, transforms CAD/CAM cutter location (CL) files into the specific machine (G/M) codes required by NC machines. With a flexible library of standard postprocessors and machine configurations, you can begin to generate NC files immediately.

The intuitive IMSpost user interface (with a checklist and Windows GUI) provides an efficient work environment that works seamlessly with all major CAD/CAM systems and hardware platforms. IMS macro processor, with source level debugger, provides support for the most complicated postprocessor configurations.

IMSpost features include:

• High speed machining

• Automatic conversion of point-to-point data to NURBS format

• User-customized interface or menus (call your own DLLs, scripts, or programs during postprocessor execution)

• Arc fitting of point-to-point data in any plane

• CL file read ahead

• Advanced linearization for multi-axis machines

• Optimized output using linear tangency

• State-of-the-art technology, using C++ and Windows GUI

• Support of all machine classes with any number of linear or rotary axes

• 5-axis drilling cycles

• Automatic support of co-linear axes

• Canned cycles or simulated drilling cycles for machines without cycle support

• Use of the same postprocessor for any CAM system or hardware platform

• Easy-to-use macro language and source level debugging tool that traces output line-by-line and statement-by-statement

• Access to all internal postprocessor variables and source code

• Conversational output style support

• User-definable postprocessor syntax

• Integrated controller emulation/reverse post technology

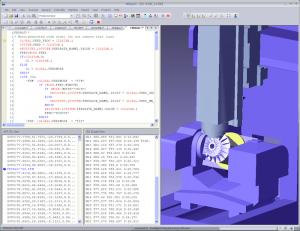

Integrated APT/CL, G-code, and machine view provide the complete picture for CNC post development.

The IMSpost virtual CNC controller offers complete analysis of the machine code and provides a true picture of the tool motion. The virtual controller provides support for NC controls from all major manufacturers.