EMCO GmbH

Productos

EMCO GmbH

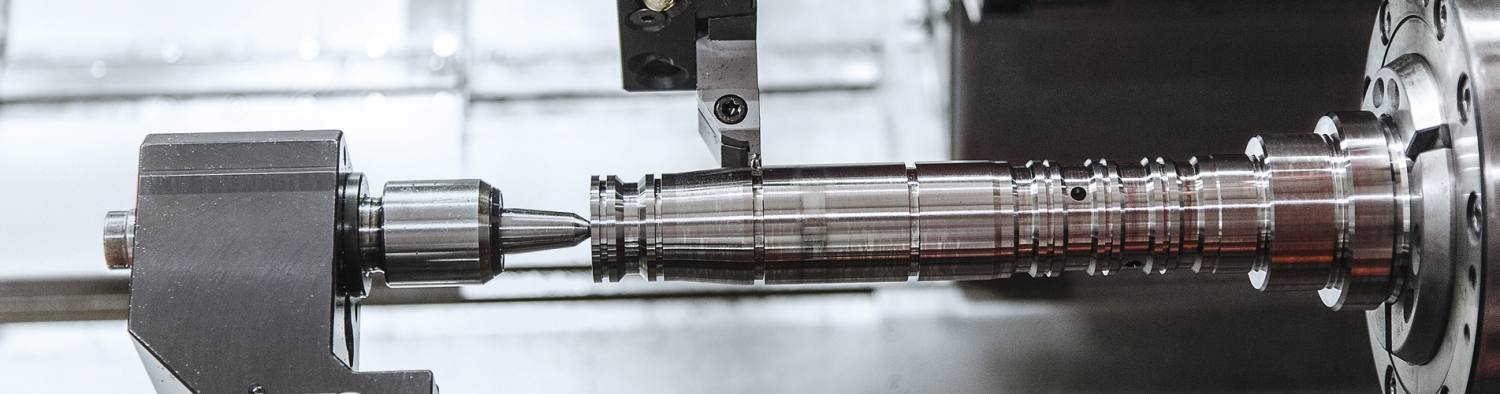

Centros de mecanizado, fresado y torneado

HYPERTURN 65

DESTACADOS

/ 2 motores de husillo de alto rendimiento y refrigerados por agua

/ 2 / 3 torretas de 12 tiempos con sistema de cambio rápido VDI 30 / 40

/ Opcional con torretas BMT y accionamiento directo hasta 12 000 rpm

/ 2 / 3 ejes Y para el mecanizado de piezas torneadas/fresadas complejas

/ Alimentación de barras hasta ø 95 mm

/ Flujo de virutas óptimo y área de trabajo de fácil manejo

/ Sinumerik ONE o FANUC 31iB a elección del cliente

/ Fabricado en el corazón de Europa

EQUIPAMIENTO

/ 2 husillos3 torretas de herramientas

/ Hasta 36 herramientas accionadas en dos o tres torretas de herramientas

/ Hasta 3 ejes Y independientes

/ Automatización con cargador de barras o de pórtico EMCO

/ EMCONNECT - Asistente de Proceso Digital (Sinumerik ONE)

Dreh- und Fräszentrum Hyperturn 65 Powermill High Performance

|

Centro de mecanizado, fresado y torneado

EMCO GmbH

Centros de mecanizado, fresado y torneado

Con dos husillos de torneado, un potente husillo de fresado con cambiador de herramientas y un almacén de 40 unidades, así como dos revólveres de herramientas inferiores con 12 posiciones accionadas cada uno, la nueva HYPERTURN 65 Powermill HP - "HIGH PERFORMANCE" - permite la máxima productividad. Especialmente cuando se trata de la producción eficiente de series pequeñas y medianas con gran variabilidad.

Translated with DeepL

HYPERTURN 65 PM G2

|

Centro de mecanizado, fresado y torneado

EMCO GmbH

Centros de mecanizado, fresado y torneado

DESTACADOS

/ Elevada dinámica gracias a la más moderna tecnología de motores de husillo

/ Todos los husillos refrigerados por líquido para una termoestabilidad óptima

/ Alta productividad gracias a los cortos tiempos de cambio de herramienta

/ Ambos sistemas de herramientas pueden utilizarse en los dos husillos

/ Diseño de bancada para máxima estabilidad y amortiguación de oscilaciones

/ Excelente repetibilidad gracias a las guías lineales

/ Tiempos de preparación cortos gracias a la facilidad de acceso a la zona de trabajo

EQUIPO

/ Husillo principal y contrahusillo, husillo de fresado, ejes B e Y

/ Torreta portaherramientas adicional con accionamiento de fresado y eje Y

/ Almacén de herramientas de cadena de 40, 80 y 120 ranuras

/ Almacén de herramientas y unidad de control colocados ergonómicamente

/ Diámetro máx. de barra 65 (102) mm

/ EMCONNECT - Asistente de proceso digital (Sinumerik ONE)

EMCO HYPERTURN 110

|

Turning and milling centre

EMCO GmbH

Centros de mecanizado, fresado y torneado

DESTACADOS

/ 2x A2-8" husillo principal y contrahusillo refrigerados por agua

/ 2x A2-11" potente husillo principal y contrahusillo

/ 2x Torreta de herramientas de 12 cavidades con sistema de cambio rápido VDI 40

/ Opcionalmente con torreta BMT y accionamiento directo hasta 6000 rpm

/ Ejes Y para el mecanizado de piezas torneadas y fresadas complejas

/ Alimentación de barras hasta ø 95/110 mm

/ Flujo de virutas óptimo y zona de trabajo cómoda para el operario

/ Máximo rendimiento de accionamiento y control

EQUIPO

/ 2 husillos eje C

/ 2 torretas de herramientas

/ Potente husillo de fresado

/ Herramientas motorizadas en ambas torretas

HYPERTURN 100

|

Centro de mecanizado, fresado y torneado

EMCO Italy

Centros de mecanizado, fresado y torneado

DESTACADOS

/ Preajustes automáticos de herramientas y sondas de medición de piezas

/ Una o varias lunetas NC

/ 40 / 100 estaciones de almacén de herramientas

/ Husillo de fresado flexible con 12000 rpm

/ Sistema de recogida de la barra de perforación

/ Mecanizado simultáneo en 5 ejes

/ Alta presión del refrigerante 80 bar

/ Supervisión de colisiones de máquinas virtuales

/ SOPORTE REMOTO EMCO

/ Control de rotura de herramientas

EQUIPO

/ Husillo principal y contrahusillo para operaciones de torneado y fresado

/ Husillo de fresado para operaciones de torneado, taladrado y fresado

/ Husillo de fresado flexible con 12.000 rpm

/ 40 / 100 estaciones de herramientas

/ Sistema de recogida de la barra de perforación

/ EMCONNECT - Asistente de Proceso Digital (Sinumerik ONE)

HYPERTURN 200 Powermill

|

Turning and milling centre

EMCO GmbH

Centros de mecanizado, fresado y torneado

DESTACADOS

/ Zona de trabajo muy amplia para el mecanizado completo de piezas de hasta 1.000 mm de diámetro de torneado con una longitud máxima de 6.100 mm.

/ Eje B dinámico y preciso con gran par y potencia

/ Dos versiones de husillos de fresado con 6500 o 10000 rpm, con HSK-T100 o PSC80 (Capto C8)

/ Multitarea y multitecnología: Sinumerik ONE

/ Husillo principal y contrahusillo: mecanizado de alto rendimiento con barra de mandrinar antivibraciones de hasta 1500 mm, incluido un almacén especial (opcional)

/ Preajuste automático de herramientas y sonda de medición de piezas

/ Una o varias lunetas NC

EQUIPO:

/ Husillo principal para operaciones de torneado y fresado.

/ Husillo de fresado para operaciones de torneado, taladrado y fresado

/ Posibilidad de elegir entre 2 husillos de fresado de alto par (6.500 rpm / 630 Nm) o de alta velocidad (10.000 rpm / 340 Nm)

/ Hasta 200 estaciones de herramientas

/ 3 estaciones adicionales para barras de mandrinar y herramientas largas

/ EMCONNECT - analista de procesos digitales (Sinumerik ONE)

HYPERTURN 45

|

Turning and milling centre

EMCO GmbH

Centros de mecanizado, fresado y torneado

HIGHLIGHTS

/ Highly dynamic drives in all axes

/ Two high-performance work spindles

/ Two highly flexible, 12-station tool turrets

/ Stable Y-axis with 70 mm travel

/ State-of-the-art control and drive technology

/ User-friendly dialog control with 3D graphics

/ Compact dimensions

/ Made in the Heart of Europe

EQUIPMENT

/ 2 spindles12-station tool turret

/ Driven tools on both turrets

/ Y axis

/ Automation with EMCO bar or swing loader

/ Siemens or Fanuc control

/ EMCONNECT ? Digital Process Assistant (Siemens 840D sl)

HYPERTURN 45 G3

|

Centro de mecanizado, fresado y torneado

EMCO GmbH

Centros de mecanizado, fresado y torneado

DESTACADOS / Amplia área de trabajo / Accionamientos altamente dinámicos en todos los ejes / Dos potentes husillos de trabajo / Torreta portaherramientas de 12 estaciones/16 estaciones con un impresionante rendimiento de fresado / Eje Y estable con recorrido de 80 mm / Asistente de proceso EMCONNECT para Sinumerik ONE / Fanuc 31ib con pantalla multitáctil de 22 / Dimensiones compactas / Fabricado en el corazón de Europa EQUIPAMIENTO / 2 husillos / Torreta de herramientas de 12 estaciones / 16 estaciones / Herramientas motorizadas en ambas torretas / Eje Y con recorrido de 80 mm / Automatización con barra EMCO o cargador giratorio / Control Siemens o Fanuc / EMCONNECT - Asistente de proceso digital (Sinumerik ONE)

HYPERTURN 65 Powermill

|

Turning and milling centre

EMCO GmbH

Centros de mecanizado, fresado y torneado

DESTACADOS

/ Gran dinamismo gracias a la tecnología punta de los motores de husillo

/ Máxima termoestabilidad gracias a los husillos refrigerados por líquido

/ Alta productividad gracias a los cortos tiempos de cambio de herramienta

/ Ambos sistemas de herramientas pueden utilizarse en los dos husillos

/ Construcción de la bancada de la máquina para máxima estabilidad y absorción de vibraciones

/ Excelente repetibilidad gracias a las guías lineales

/ Tiempos de preparación cortos gracias a una zona de trabajo de fácil acceso

EQUIPO

/ Husillo principal y contrahusillo, husillo de fresado, ejes B e Y

/ Torreta portaherramientas adicional con accionamiento de fresado y eje Y

/ Almacén de herramientas de cadena de 20, 40 u 80 ranuras

/ Almacén de herramientas y unidad de control colocados ergonómicamente

/ Diámetro máx. de barra 65 (76,2 / 95) mm

/ EMCONNECT - Asistente de proceso digital (Sinumerik ONE)

HYPERTURN 95

|

Turning and milling centre

EMCO GmbH

Centros de mecanizado, fresado y torneado

DESTACADOS

/ 2x A2-8" husillo principal y contrahusillo refrigerados por agua

/ 2x A2-11" potente husillo principal y contrahusillo

/ 2x Torreta de herramientas de 12 cavidades con sistema de cambio rápido VDI 40

/ Opcionalmente con torreta BMT y accionamiento directo hasta 6000 rpm

/ Ejes Y para el mecanizado de piezas torneadas y fresadas complejas

/ Alimentación de barras hasta ø 95/110 mm

/ Flujo de virutas óptimo y zona de trabajo cómoda para el operario

/ Máximo rendimiento de accionamiento y control

EQUIPO

/ 2 husillos eje C

/ 2 torretas de herramientas

/ Potente husillo de fresado

/ Herramientas motorizadas en ambas torretas